1. Introduction

Les trépans rotatifs sont les bêtes de somme de la technologie de forage moderne. Placés tout en bas du train de tiges, ils servent d'interface de coupe entre l'équipement technique en surface et les formations souterraines à pénétrer. Sans eux, aucun forage ne pourrait être réalisé, qu'il s'agisse d'extraire des hydrocarbures, d'accéder à des nappes phréatiques, de faire sauter des roches dans des mines ou d'installer les fondations de gratte-ciel.

Bien que le concept d'un outil rotatif creusant la terre puisse sembler simple, les trépans rotatifs sont le résultat de décennies de perfectionnement technique. Leur conception reflète un équilibre entre l'efficacité mécanique, la science des matériaux et l'adaptation géologique. Cet article explore l'utilisation des trépans rotatifs, leur fonctionnement, les différents types disponibles, leurs applications dans les différentes industries, les facteurs qui guident la sélection et les défis auxquels les opérateurs sont confrontés pour maximiser les performances.

Comparaison des principaux types de forets rotatifs

| Type de bit | Mécanisme de coupe | Formations typiques | Avantages | Limites |

|---|---|---|---|---|

| Roller-Cone (Tricone) | Écrasement + gougeage | Mixte, fracturé, abrasif | Polyvalence, prise en charge des couches imbriquées, flexibilité des coûts | Usure des roulements, réduction du ROP dans les roches tendres |

| PDC (fraise fixe) | Cisaillement | Doux à moyennement dur, homogène | Taux de pénétration élevés, fraises durables, orientables | Dommages causés par les fraises dans les zones dures ou sujettes aux chocs |

| Imprégné de diamant | Abrasion + broyage | Très dur, abrasif (quartz, granit) | Extrêmement durable dans les roches dures | ROP plus faible, coût plus élevé |

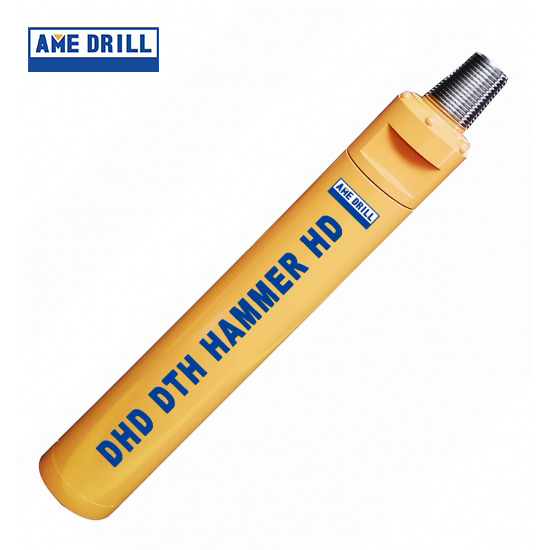

| Marteaux DTH | Percussion + rotation | Formations denses et ultra-dures | Pénètre efficacement dans les roches les plus dures | Besoin élevé en air/énergie |

| Bits de base | Coupe + carottage | Exploration, géotechnique | Récupération de carottes intactes | Plus lent, limité à l'échantillonnage |

2. Principe de fonctionnement de base des forets rotatifs

Le rôle fondamental d'un trépan rotatif est de convertir l'énergie de rotation et la force descendante dans la fragmentation de la roche. Lorsque le train de tiges tourne, le trépan applique un poids sur le trépan (WOB) à la formation. La roche est fragmentée par l'un des trois mécanismes suivants :

- Cisaillement - couper ou trancher la roche, ce qui est typique des mèches à coupe fixe comme les modèles à diamant compact polycristallin (PDC).

- Broyage - comprimer la roche jusqu'à ce qu'elle se fracture, ce qui est courant dans les trépans à cône (tricônes).

- Abrasion - le broyage de formations très dures, souvent à l'aide de mèches matricielles imprégnées de diamant.

Tout aussi important est le rôle des fluide de forage (boue ou air). Ce fluide s'écoule à l'intérieur du train de tiges, sort par les buses du trépan et circule jusqu'à la surface. Ses fonctions sont les suivantes

- Refroidir le bit, en évitant la dégradation thermique.

- Retirer les déblais du trou de forage, en évitant le colmatage ou le réaffûtage.

- Stabiliser les parois du trou de forage.

Il en résulte un cycle continu : le trépan fracture la roche, le fluide élimine les débris et le trou de forage s'étend vers le bas.

Produits recommandés

Applications courantes des mèches rotatives

| L'industrie | Types de bits couramment utilisés | Objectif |

|---|---|---|

| Pétrole et gaz | PDC, Tricone, Hybride | Forage de puits d'exploration et de production |

| Mines et carrières | Tricone de grand diamètre, DTH | Forage à l'explosif pour l'extraction du minerai |

| Puits d'eau | Tricone, PDC | Accès aux aquifères, approvisionnement municipal et agricole |

| Géothermie | PDC, tricône, imprégné de diamant | Pénétration dans les formations dures à haute température |

| Génie civil | Tricone, carottes | Forage de fondations, étude du sol et de la roche, micropieux |

| Disque dur (utilitaires) | PDC, alésoirs | Installation de pipelines et de câbles sous les rivières, les autoroutes ou les zones urbaines |

3. Principaux types de forets rotatifs

Les trépans rotatifs ne sont pas des outils à taille unique. Les ingénieurs choisissent parmi plusieurs catégories, chacune étant optimisée pour des types de roches et des exigences opérationnelles spécifiques.

3.1 Couronnes à rouleaux (tricônes)

Développés au début du 20e siècle, les trépans à cônes demeurent une pierre angulaire du forage. Ils se composent de trois cônes rotatifs, chacun doté de dents en acier ou d'inserts en carbure de tungstène. En roulant sur la formation, les cônes écrasent et entaillent la roche.

Avantages :

- Polyvalent dans une large gamme de formations.

- Tolère les géologies mixtes ou fracturées.

- Disponibles avec des roulements étanches ou refroidis par air.

Limites :

- Complexité mécanique accrue (les roulements et les joints sont des points de défaillance).

- Taux de pénétration plus faibles dans les formations homogènes, tendres à moyennes par rapport aux PDC.

3.2 Fraises à coupe fixe (fraises PDC et fraises diamantées)

Les mèches à fraise fixe n'ont pas de cônes mobiles ; elles utilisent des fraises fixées en place.

- Bits PDC : Utilise des fraises en diamant synthétique brasées sur le corps du trépan. Elles cisaillent la roche dans un mouvement de tranchage continu, ce qui permet d'obtenir des taux de pénétration élevés dans de nombreuses formations.

- Mèches imprégnées de diamant : Ils contiennent des particules de diamant naturel ou synthétique intégrées dans une matrice. Ils excellent dans les formations très dures et abrasives où les autres trépans échouent.

Avantages :

- Peu de pièces mobiles, d'où une durée de vie potentiellement plus longue.

- Très grande efficacité dans les formations appropriées.

- Bien adapté aux forages directionnels et horizontaux.

Limites :

- Sensible aux impacts et aux vibrations dans les formations hétérogènes.

- Peut être coûteux s'il est utilisé dans des conditions géologiques inadaptées.

3.3 Bits spécialisés

- Marteaux fond de trou (DTH) : Utilisé avec des marteaux pneumatiques pour le forage de roches extrêmement dures.

- Alésoirs et ouvre-trous : Agrandir les trous pilotes existants pour obtenir des diamètres plus importants.

- Bits de base : Récupérer des échantillons de roches cylindriques pour des analyses géotechniques ou d'exploration.

| Type de bit | Taux de pénétration (ROP) (m/hr) | Durée de vie moyenne des bits (mètres forés) | Coût relatif | Meilleur environnement |

|---|

| Tricone | 3 - 10 | 150 - 300 | Moyen | Formations mixtes, roches fracturées |

| PDC | 8 - 25 | 500 - 2,000 | Haut | Formations schisteuses molles-moyennes, homogènes |

| Imprégné de diamant | 1 - 5 | 2,000 - 5,000 | Très élevé | Roche cristalline ultra-dure et abrasive |

| Marteau DTH | 2 - 8 | 100 - 400 | Moyenne-élevée | Rock extrêmement dur nécessitant des percussions |

4. Applications industrielles des forets rotatifs

Les forets rotatifs sont utilisés dans un nombre impressionnant d'industries :

4.1 Exploration pétrolière et gazière

Les trépans rotatifs sont indispensables au forage des puits de pétrole et de gaz. Leur conception influence directement le taux de pénétration (ROP), la stabilité des puits directionnels et l'économie générale du forage. Dans les schistes tendres, les trépans PDC dominent, tandis que dans les formations abrasives ou interstratifiées, les trépans à cône restent précieux.

4.2 Mines et carrières

Les trépans rotatifs de grand diamètre sont courants dans les mines à ciel ouvert. Ils forent des trous pour les explosifs, permettant une fragmentation efficace de la roche et la récupération du minerai. Ces trépans sont conçus pour durer, car les temps d'arrêt dans les exploitations minières entraînent des coûts considérables.

4.3 Puits d'eau et forages géothermiques

L'accès aux eaux souterraines et aux réservoirs géothermiques nécessite la pénétration de diverses couches géologiques. Les entrepreneurs passent souvent d'un type de trépan à l'autre lorsqu'ils rencontrent du sable, du gravier, du schiste et de la roche mère. Les PDC et les tricônes sont tous deux largement utilisés.

4.4 Construction et ingénierie géotechnique

Les ingénieurs civils font appel au forage rotatif pour les fondations profondes, les micropieux, les structures de soutènement et l'étude des sols. Les trépans sont choisis en fonction de la vitesse, de la précision ou de la récupération des carottes exigées par le projet.

4.5 Services publics et forage directionnel horizontal (HDD)

Les trépans rotatifs guident les forages sous les rivières, les routes ou les infrastructures urbaines pour les pipelines et les câbles. Les trépans de type PDC sont préférés en raison de leur maniabilité et de leurs performances constantes.

Modes courants de défaillance des bits

| Mode de défaillance | Cause | Impact |

|---|---|---|

| Défaillance du palier | Chaleur, contamination, défaillance du joint (tricone) | Perte soudaine de fonction |

| Usure des couteaux | Contact permanent avec des formations abrasives | Taux de pénétration réduit, forage inefficace |

| Boule de mors | Accumulation de débris collants (schistes, argiles) | Bloque les canaux d'écoulement, bloque le forage |

| Dommages par impact | Cordons durs, inclusions inattendues | Ébréchure de la lame, rupture catastrophique |

| Dégradation thermique | Refroidissement insuffisant dans les environnements à haute température | Perte de la fraise diamantée, durée de vie réduite |

5. Facteurs influençant le choix des bits

Le choix du bon trépan rotatif est un équilibre entre la géologie, l'économie et la conception technique. Les facteurs critiques sont les suivants :

- Type de formation :

- Formations meubles, non consolidées → PDC ou trépans.

- Formations dures et abrasives → cônes à rouleaux ou trépans diamantés.

- Zones interstratifiées ou fracturées → roller-cones pour la tolérance.

- Objectifs opérationnels :

- Taux de pénétration élevé par rapport à une durée de vie maximale de la mèche.

- Le forage directionnel nécessite une stabilité et un comportement prévisible de la surface de l'outil.

- Environnement de forage :

- Circulation de la boue par rapport à la circulation de l'air, température et pression du fond de puits.

- Considérations économiques :

- Coût du trépan par rapport au coût par mètre foré.

- Temps d'arrêt potentiel pour le remplacement de l'embout.

6. Principales caractéristiques de conception et innovations

Les mèches rotatives modernes intègrent des technologies de pointe :

- Optimisation des plaquettes et des carbures : Géométries variées (burin, conique, sphérique) et nuances de carbure adaptées aux différentes résistances à la compression.

- Amélioration des roulements et des joints : Les paliers lisses étanches, les joints en élastomère et les réservoirs de graisse prolongent la durée de vie du trépan.

- Améliorations hydrauliques : L'emplacement optimisé des buses garantit l'efficacité de l'évacuation des débris et du refroidissement.

- Matériaux avancés : Aciers à haute résistance, corps à matrice composite et fraises diamantées thermiquement stables.

- Conception de bits hybrides : Combinaison de cônes à rouleaux et d'éléments PDC pour exploiter plusieurs mécanismes de coupe.

- Modélisation numérique : Les simulations informatiques permettent de prévoir les interactions entre le bit et la roche, ce qui aide les ingénieurs à optimiser les conceptions avant le déploiement.

7. Défis et limites

Malgré les progrès technologiques, les trépans rotatifs sont confrontés à des risques opérationnels :

- Usure et abrasion : Le contact continu avec la roche abrasive entraîne l'émoussement des couteaux.

- Défaillance du palier : La contamination, la surchauffe ou la défaillance d'un joint peuvent entraîner l'arrêt prématuré d'un trépan à cône.

- Le bit-balling : L'accumulation de débris peut bloquer les voies de circulation des fluides et réduire l'efficacité.

- Vibration et instabilité : Le glissement, les vibrations latérales ou le tourbillonnement peuvent raccourcir la durée de vie de l'embout.

- Dommages d'impact : Un contact soudain avec des inclusions dures inattendues peut fracturer les fraises.

Les opérateurs gèrent ces risques en sélectionnant correctement les trépans, en surveillant le forage en temps réel et en évaluant en permanence les performances.

8. Exemples de cas

8.1 Forage minier à l'explosif

Une mine à ciel ouvert utilisant de grands trépans rotatifs a choisi des inserts en carbure de tungstène. En optimisant la géométrie des plaquettes et la conception des paliers, la mine a prolongé la durée de vie des tricônes de 20%, réduisant ainsi les temps d'arrêt et améliorant le coût par tonne de minerai extrait.

8.2 Forage de puits d'eau dans des formations mixtes

Un entrepreneur chargé de forer un puits municipal a rencontré des couches alternées de gravier, d'argile et de schiste. Le passage d'un trépan PDC à un tricône dans le schiste fracturé a permis de maintenir la pénétration sans vibrations excessives ni dommages à l'outil de coupe.

8.3 Forage de sections pétrolières et gazières

Dans un puits de gaz de schiste profond, les ingénieurs ont utilisé des trépans PDC pour les longues sections horizontales, bénéficiant ainsi d'un rendement élevé et d'une grande stabilité. Cependant, lors du forage d'un intervalle de carbonate dur, ils ont opté pour un trépan à cône à rouleaux afin de tolérer les charges d'impact et d'éviter d'endommager l'outil de coupe.

9. Conclusion

Les forets rotatifs sont bien plus que de simples outils de coupe - ils sont des interfaces très élaborées entre les systèmes construits par l'homme et la géologie naturelle. Leurs applications couvrent l'exploration pétrolière et gazière, l'exploitation minière, la construction, les puits d'eau, le forage géothermique et l'installation d'infrastructures.

Le choix du type de trépan, de sa conception et de ses paramètres opérationnels influence directement l'efficacité du forage, le coût du projet et sa réussite. Grâce aux progrès constants des matériaux, de la technologie des fraises et de la modélisation numérique, les trépans rotatifs évoluent vers une durée de vie plus longue, des taux de pénétration plus élevés et un coût global plus faible par mètre foré.

En bref, les forets rotatifs sont les catalyseurs essentiels de l'industrie moderneL'Union européenne est l'un des pays les plus riches du monde en matière d'énergie, rendant possible tout ce qui va de l'électricité qui alimente nos maisons aux fondations de nos villes.