Friction welding originated over a century ago, and after more than half a century of research and development, friction welding technology has matured and entered the stage of widespread application. Since the 1950s, when qualified weld joints were first successfully achieved by friction welding, it has garnered attention from all industrialized nations due to its high quality, efficiency, low consumption, and environmental benefits.

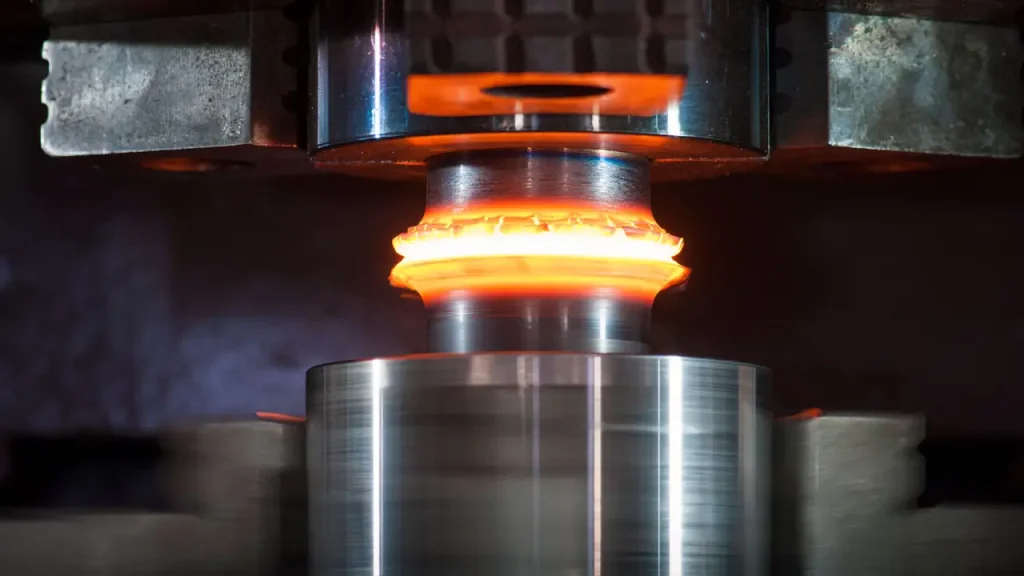

The friction welding process for DTH drill pipes uses the heat generated by the friction at the contact surfaces of the workpieces, which under pressure, causes plastic deformation, thus facilitating the welding.

What is Friction Welding?

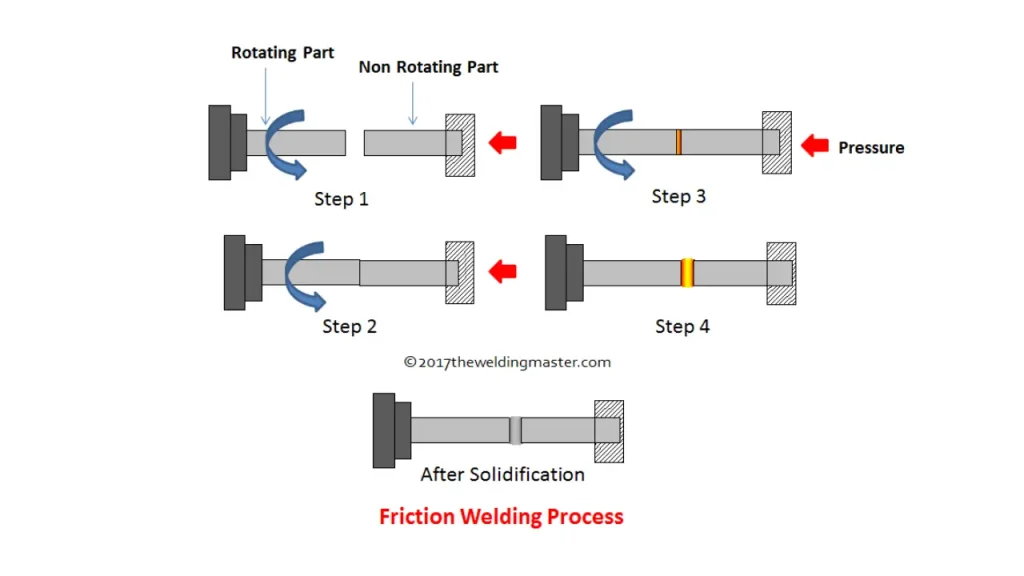

Friction welding is a solid-state joining process that creates a high-integrity bond between two materials without melting them. It works by bringing two workpieces into contact under pressure while one is rotated or oscillated rapidly against the other.

The mechanical friction generates intense heat at the interface, causing the material to soften and reach a plastic state. As the rotation or oscillation ceases, a high axial force is applied, forging the plasticized material together and expelling any impurities, resulting in a strong metallurgical bond. This process is particularly advantageous for joining dissimilar metals and producing welds with superior mechanical properties.

Principle of Friction Welding

The principle of friction welding involves using the relative motion between the welding contact surfaces to generate friction heat and plastic deformation, raising the temperature around the contact area to near the melting point.

At this temperature, the material becomes more pliable, and its resistance to deformation decreases. With this plastic deformation, the rod and joint under pressure join through interface recrystallization and molecular diffusion.

Friction-Welded Drill Pipes

Friction-welded drill pipes represent a pinnacle in drilling tool technology, offering superior performance and longevity in the most demanding environments. This advanced manufacturing technique creates a robust bond between the rod body and tool joint, significantly enhancing the rod’s overall strength and reliability.

- Enhanced Strength and Durability: Friction welding creates a solid-state metallurgical bond that is often stronger than the parent material, ensuring the drill pipe can withstand extreme torsional and axial stresses encountered during aggressive drilling operations, leading to extended service life and reduced failures.

- Optimal Power Transfer: The high-integrity joint ensures efficient transfer of drilling power from the rig to the bit. This seamless connection minimizes energy loss and maximizes drilling efficiency, translating into faster penetration rates and improved productivity in various geological formations.

- Resistance to Fatigue and Wear: The process minimizes the heat-affected zone, preserving the material properties and significantly improving the rod’s resistance to fatigue cracking and abrasive wear. This resilience is crucial for maintaining performance in challenging and abrasive drilling conditions over prolonged periods.

- Versatility in Applications: Friction-welded drill pipes are suitable for a wide range of drilling methods, including DTH (Down-The-Hole), top hammer, and rotary drilling. Their robust construction and reliable performance make them ideal for diverse applications in mining, construction, and water well drilling.

Friction Welding Process

Prepare the DTH drill pipe joint and body, and align them to ensure co-axial alignment during welding. Start the friction welding machine to rotate the joint at a specific speed while applying axial pressure to the DTH drill pipe body to begin friction heating. When the friction surfaces of the joint and rod body reach the welding temperature, stop rotation. Simultaneously with the cessation of rotation, apply greater axial pressure to perform a forge pressing.

Maintain this forge pressure for a period, then let the joint cool naturally to room temperature. After a period of cooling, the material in the weld joint re-solidifies to form a robust connection. After friction welding, the welded area of the DTH drill pipe and joint often experiences defects such as poor mechanical properties and unstable microstructure.

Therefore, it is necessary to carry out heat treatment of the weld area, specifically quenching followed by high-temperature tempering, to achieve a uniform and stable weld structure with good overall mechanical properties.

Friction Welding Advantages

- Short welding construction time and high production efficiency.

- High weld quality, typically free from weld spatter, with high post-weld dimensional accuracy.

- Welding does not produce smoke, arc light, or harmful gases, thereby avoiding pollution.

- High degree of mechanization and automation, consistent welding quality.

During drilling operations, DTH drill pipes are subjected to various complex loads such as bending, twisting, compression, and tension, making safety paramount. Friction-welded DTH drill pipes exhibit strong bending resistance, good flexibility, and wear resistance, which contributes to their widespread application.

Conclusion

In conclusion, friction welding is a critical process for DTH drill pipes, ensuring strong bonds between the rod body and tool joints. This solid-state technique, involving preparation, rotational heating, and forging, creates exceptionally durable connections. The DTH drill pipes supplied by Ame Drill are produced by this method to guarantee high-performance, long-lasting drill pipes for demanding applications.

The benefits of friction welding, such as superior strength and minimal heat impact, directly enhance the reliability of Ame Drill’ DTH drill pipes. This advanced manufacturing ensures consistent, top-tier performance, boosting productivity and reducing operational downtime for drilling professionals. Our drill pipes are built to withstand the most challenging conditions.

For drill pipes that offer unparalleled quality and durability, choose Ame Drill. Contact us today to get wholesale friction-welded DTH drill pipes! Our team is dedicated to providing you with the robust, high-integrity tools you need to succeed in any drilling environment.