How to match the hammer to the correct pipe diameter

Pipe diameter should be close to the hammer diameter to provide optimum flushing, reducing the chances of getting stuck in the hole.

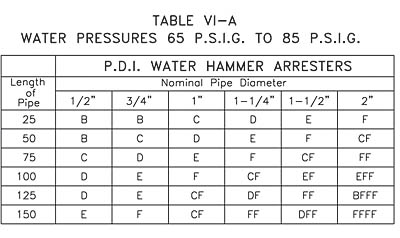

Selection of the water hammer arrestor is based upon the total quantity of fixture units on each cold and hot water branch line. FIXTURE TYPE OF SUPPLY CONTROL WEIGHT IN FIXTURE UNITS C.W. H.W. C.W. H.W. Determine the total number of fixture units on each branch line by referring to the list of fixtures in Table One.

Key features to look for in high-quality DTH pipes are durability

Accuracy and manageability. Pipes (tubes) made from cold-drawn tubing provide a superior surface finish and tolerance compared with tubes made from hot-rolled tubing. A better finish reduces the risk of metal chips from the tubes, called scaling. Scaling that flows through the hammer is a major cause of premature hammer failure.

Construction quality is at least as important as design. Friction-welded joints add strength. Heat treating the threads of end pieces ensures optimum durability and strength of the thread profile, which results in longer thread life. Preserving the thread profile keeps coupling and uncoupling smooth, without adding time to the average rate of penetration—in other words, the cost per foot to complete holes.

In most applications, standard API threads are the best choice, although adapter subs and crossover subs are available to support any setup.