Introduction

Dans le domaine en constante évolution de l'ingénierie géotechnique, murs de clouage du sol se sont imposés comme une technique remarquablement efficace et polyvalente pour la rétention des terres et la stabilisation des pentes. Cette méthode innovante, qui consiste à renforcer le sol in situ à l'aide d'éléments étroitement espacés appelés "clous", a révolutionné la façon dont nous abordons les projets de construction impliquant des excavations, des remblais et des structures de retenue. Développé à l'origine dans les années 1970 grâce à des efforts indépendants en France, en Allemagne et aux États-Unis, le clouage du sol est devenu depuis une technique fondamentale dans le développement d'infrastructures modernes dans le monde entier.

Le concept fondamental du clouage de sol est élégamment simple mais profondément efficace : il transforme des masses de sol vulnérables en systèmes stables et autoportants en améliorant la résistance naturelle au cisaillement du sol par l'installation d'éléments de renforcement. Ce processus crée une matériau composite qui se comporte de la même manière qu'un mur de soutènement par gravité, mais qui offre une plus grande flexibilité, un meilleur rapport coût-efficacité et une meilleure adaptabilité aux conditions difficiles du site. Alors que les projets de construction sont de plus en plus confrontés à des contraintes liées à la densité urbaine, aux préoccupations environnementales et aux limitations budgétaires, les avantages des murs de soutènement par gravité sont de plus en plus importants. murs de clouage du sol deviennent de plus en plus précieuses pour les ingénieurs et les entrepreneurs.

Cet article explore les principes d'ingénierie, les avantages, les applications et les développements futurs de la technologie du clouage de sol, en fournissant une vue d'ensemble complète des raisons pour lesquelles cette méthode est devenue un choix privilégié pour de nombreux scénarios de construction difficiles aux États-Unis et au-delà.

Comprendre les murs de clous de sol : Mécanisme et composants

Définition et principes de base

A sol clou mur est un technique de renforcement du sol in situ qui consiste à installer dans le sol des éléments minces et très espacés (clous) afin de créer une masse composite stable. Ces clous sont généralement constitués de barres d'armature en acier qui sont scellées dans des trous pré-percés, bien que d'autres types de clous puissent être enfoncés ou vissés. La masse de sol renforcée est associée à un élément de parement, généralement du béton projeté armé d'un treillis métallique, pour former une structure cohérente capable de résister à l'érosion. pression latérale des terres et le maintien de la stabilité des pentes.

Le mécanisme fondamental par lequel les clous de sol fonctionnent implique le transfert des forces de traction et de cisaillement de la zone instable du sol vers des couches plus stables. Lorsque le sol commence à se déformer, les clous interagissent avec le sol environnant en mobilisant les contraintes de cisaillement le long de l'interface clou-sol. Cette interaction génère une tension dans les clous, qui à son tour fournit des forces de retenue qui augmentent la résistance du sol. la résistance au cisaillement du sol et réduire les déformations.

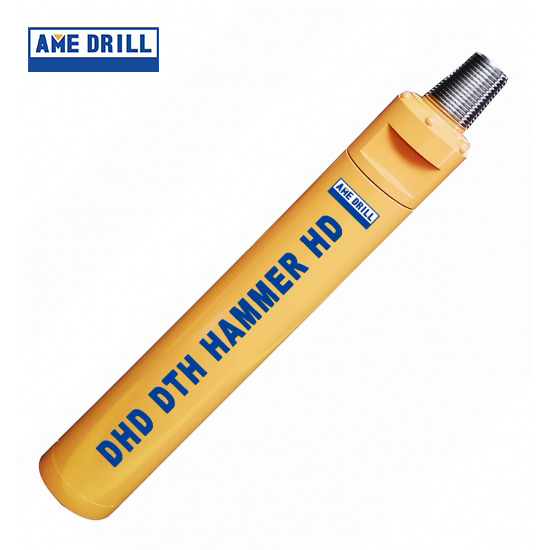

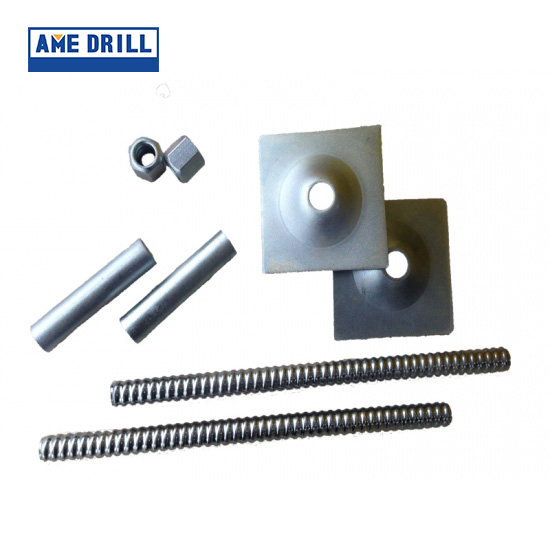

Produits les mieux notés

Composants clés

- Clous de sol: Les éléments d'armature primaires, généralement constitués de barres d'acier (16-32 mm de diamètre) ou de tubes d'acier, sont installés dans des trous forés et scellés en place.

- Système de façade: Se compose généralement de béton projeté (généralement 80-100 mm d'épaisseur, avec une résistance à la compression ≥20MPa) renforcé par un treillis métallique, qui assure la protection de la surface et aide à répartir les charges entre les clous.

- Plaques de roulement: Plaques d'acier placées à la tête des clous qui transfèrent les forces du parement aux clous.

- Système de drainage: Crucial pour éviter l'accumulation de pression d'eau derrière le mur, y compris les trous d'évacuation et les tuyaux de drainage.

La science derrière le clouage du sol

L'efficacité du clouage du sol provient de sa capacité à améliorer les propriétés inhérentes du sol. L'installation de clous augmente la cohésion apparente de la masse du sol par le biais de trois mécanismes principaux :

- Contrainte cinématique: Les clous coupent les surfaces de rupture potentielles, offrant une résistance à la déformation par cisaillement.

- Effet de confinement: Les clous créent une zone renforcée qui confine le sol, limitant ainsi les déformations latérales.

- Redistribution du stress: Les charges sont transférées des zones les plus sollicitées vers les zones moins sollicitées par le biais du renforcement des clous.

Ce système composite s'attaque efficacement à la faiblesse fondamentale du sol - sa faible résistance à la traction - en introduisant des éléments de résistance à la traction qui travaillent en harmonie avec la résistance à la compression naturelle du sol.

Tableau : Composants et spécifications typiques d'une paroi clouée au sol

| Composant | Matériau/Type | Spécifications typiques | Objectif |

|---|---|---|---|

| Clous de sol | Barres de renforcement en acier | Diamètre : 16-32 mm Espacement : 1-2m Longueur : 0,5-1,2x la hauteur du mur | Renforcement primaire |

| Face | Béton projeté avec treillis métallique | Épaisseur : 80-100 mm Résistance : ≥20MPa Maille : 6-10mm @ 150-300mm | Protection des surfaces, répartition des charges |

| Plaques de roulement | Acier | Taille : 200x200mm à 300x300mm Épaisseur : 15-25 mm | Transférer la force du parement aux clous |

| Coulis | Ciment | Rapport eau-ciment : 0,4-0,5 Résistance : ≥20MPa | Protection contre la corrosion, liaison sol-clou |

Avantages des murs cloués au sol dans la construction moderne

Rapport coût-efficacité

L'un des principaux avantages du clouage de sol est qu'il permet de l'efficacité économique. Des études comparatives ont systématiquement montré que les murs en terre clouée coûtent généralement un tiers à un cinquième de moins que les systèmes de murs de soutènement traditionnels tels que les murs en béton coulé sur place ou les systèmes de pieux et de calage. Cet avantage financier est dû à plusieurs facteurs :

- Réduction des besoins en matériaux: Le clouage de sol utilise le sol existant comme principal matériau structurel, minimisant ainsi le besoin de matériaux importés.

- Une construction plus rapide: La possibilité d'excaver et de renforcer par étapes séquentielles permet de réduire les délais de l'ensemble du projet.

- Réduction des coûts d'équipement: L'équipement nécessaire pour le clouage du sol (foreuses, équipement pour le béton projeté) est généralement plus petit et moins coûteux que celui nécessaire pour les systèmes alternatifs.

Une analyse comparative des systèmes de murs de soutènement publiée en 2025 a indiqué que les murs de clous de sol pouvaient permettre de réaliser des économies de 30 à 50% par rapport aux murs en terre stabilisée mécaniquement (MSE) et de 40 à 60% par rapport aux murs en béton coulé sur place pour les applications appropriées.

Perturbation minimale du site et efficacité de l'espace

Le clouage du sol nécessite une peu d'espace de travailIl est donc idéal pour les chantiers urbains contraignants où les limites de propriété jouxtent les excavations ou lorsque l'infrastructure existante limite l'espace disponible. Contrairement aux techniques qui nécessitent de grandes excavations pour le coffrage ou l'accès de l'équipement lourd, l'équipement de clouage du sol est généralement compact et maniable.

Cet avantage d'une empreinte minimale est particulièrement précieux dans les projets d'infrastructure urbaine, l'élargissement des autoroutes dans les zones développées et les réparations adjacentes aux structures existantes où les systèmes de retenue conventionnels ne seraient pas pratiques ou impossibles à construire sans l'acquisition d'une propriété supplémentaire importante.

Rapidité et efficacité de la construction

Les processus de construction séquentiel Le clouage du sol - où l'excavation, l'installation des clous et l'application du revêtement se déroulent en cycles répétitifs - permet d'obtenir une meilleure qualité de vie. des progrès continus sans les périodes d'attente généralement associées au durcissement du béton ou à d'autres processus dépendant du temps. Ce flux de travail efficace permet souvent de réaliser des parois clouées en la moitié du temps requis pour les systèmes alternatifs.

Ce gain de temps se traduit non seulement par des économies, mais aussi par une réduction de l'exposition aux retards liés aux conditions météorologiques et par une diminution du risque global lié à l'allongement de la durée d'ouverture des fouilles, ce qui est particulièrement important dans les régions soumises à des contraintes météorologiques saisonnières.

Adaptabilité et polyvalence

Les murs en clous de sol démontrent une remarquable l'adaptabilité aux différentes conditions du site. Pendant la construction, les ingénieurs peuvent modifier la longueur, l'espacement ou l'orientation des clous en fonction des conditions réelles rencontrées, ce qui facilite la mise en place d'un système de contrôle de la qualité. ajustements en temps réel qui améliorent la sécurité et les performances globales. Cette flexibilité contraste fortement avec les systèmes plus rigides qui exigent une connaissance précise des conditions du sol avant la construction.

La technique s'applique à un large éventail de types de sols, y compris les argiles, les limons, les sables, les graviers et les roches altérées, à condition que les méthodes d'installation et les paramètres de conception soient adaptés en conséquence.

Performance sismique

Les recherches et les performances réelles lors d'événements sismiques ont démontré que les murs à clous en terre présentent les caractéristiques suivantes une résistance exceptionnelle aux charges sismiques. Leur nature flexible leur permet d'absorber les déformations du sol sans défaillance catastrophique. Parmi les performances documentées, on peut citer

- Lors du tremblement de terre de Loma Prieta en 1989 (magnitude 7,1) en Californie, huit murs en clous de sol soumis à une accélération estimée à 0,4 g n'ont subi aucun dommage.

- Après le tremblement de terre de Wenchuan en 2008 (d'une magnitude de 8,0) en Chine, les infrastructures de transport soutenues par des murs de clous en terre sont restées praticables avec des dommages minimes.

Cette résilience sismique rend le clouage de sol particulièrement utile dans les régions sujettes aux tremblements de terre, comme l'ouest des États-Unis, où les infrastructures doivent résister à des charges sismiques importantes.

Compatibilité environnementale

Le processus de clouage du sol génère un minimum de déchets et faible impact sur l'environnement par rapport à d'autres systèmes. Étant donné qu'il utilise principalement le matériau in situ, il n'est pas nécessaire d'éliminer le sol excavé ou d'importer des matériaux étrangers. Le processus génère également moins de bruit, de vibrations et de perturbations de la circulation que les techniques nécessitant l'enfoncement de pieux ou l'utilisation d'équipements d'excavation à grande échelle.

Considérations d'ingénierie pour les murs de clous de sol

Adéquation et limites du sol

Bien que le clouage du sol offre de nombreux avantages, son application réussie dépend fortement d'une approche appropriée. conditions du sol. La technique fonctionne le mieux dans les sols qui ont une certaine cohésion inhérente et qui peuvent rester sans support pendant de courtes périodes au cours de la séquence de construction.

Tableau : Aptitude du sol à la construction de clous de sol

| Type de sol | Adéquation | Considérations |

|---|---|---|

| Sols argileux | Moyen à bon | Doit évaluer le potentiel de fluage ; peut nécessiter des levées d'excavation plus courtes |

| Sols limoneux | Bon | Généralement adapté avec un drainage adéquat |

| Sols sableux | Bon à excellent | Nécessite une attention particulière aux techniques de forage |

| Sols graveleux | Bon | Peut nécessiter un équipement de forage spécial |

| Roche altérée | Excellent | Résistance élevée à l'arrachement souvent obtenue |

| Sols organiques | Pauvre | Généralement inadapté en raison de sa faible résistance et de son potentiel de fluage |

| Argiles douces pures | Pauvre | Manque de temps d'attente, faible force d'adhérence des ongles |

Les sols dont la valeur N du test de pénétration standard (SPT) est inférieure à 10 doivent généralement faire l'objet d'une attention particulière et peuvent ne pas être économiquement viables pour le clouage. De même, les sols présentant des nappes phréatiques élevées peuvent nécessiter un assèchement avant l'installation des clous.

Principes de conception et méthodologies

La conception d'un mur de clous de sol moderne incorpore l'analyse de l'équilibre limite pour évaluer la stabilité interne et externe dans diverses conditions de charge. Le processus de conception prend généralement en compte

- Stabilité interne: Evaluation de la capacité de traction des clous, de la résistance à l'arrachement des clous et de la capacité d'affrontement

- Stabilité externe: Évaluation de la stabilité globale, de la résistance au glissement, de la capacité portante et du tassement

- Aptitude au service: Garantir que les déformations restent dans des limites acceptables pour l'application spécifique

L'administration fédérale des autoroutes des États-Unis (U.S. Federal Highway Administration) Circulaire sur l'ingénierie géotechnique n° 7 fournit des conseils complets sur la conception des parois cloutées, couvrant à la fois les applications temporaires et permanentes. La conception moderne utilise souvent des logiciels sophistiqués qui permettent une analyse rapide des multiples modes de défaillance et des scénarios de conception.

Considérations relatives à la gestion de l'eau

Correct gestion de l'eau est essentielle à la performance des murs en terre clouée. La pression de l'eau derrière le mur peut réduire considérablement la stabilité en diminuant la contrainte effective dans le sol et en ajoutant des surcharges. La conception doit inclure

- Drainage de surface: Détourner les eaux de surface de la crête du mur

- Drainage souterrain: Installation de chantepleures, de tuyaux de drainage ou de drains géocomposites pour soulager la pression de l'eau.

- Étanchéité: Dans certains cas, l'application d'une membrane d'étanchéité sur la face

Protection contre la corrosion

Pour les installations permanentes, protection contre la corrosion des éléments en acier est primordiale. Le niveau de protection requis dépend de la durée de vie prévue et des conditions environnementales, avec des options allant d'une simple couverture de coulis à des systèmes de double protection contre la corrosion incorporant un revêtement époxy, des gaines en plastique ondulé et un coulis de ciment.

Les lignes directrices de la FHWA proposent une approche systématique de la protection contre la corrosion en fonction de l'agressivité du sol et de la durée de vie prévue, garantissant ainsi la durabilité à long terme des installations permanentes.

Applications de la technologie de clouage des sols

Soutien temporaire à l'excavation

Le clouage du sol est largement utilisé pour support d'excavation temporaire lors de la construction d'un bâtiment, en particulier dans les zones urbaines où l'espace est limité. Sa capacité à être construit sans empiéter sur les propriétés adjacentes le rend idéal pour les excavations en bordure de terrain où d'autres techniques ne seraient pas pratiques.

Rétention permanente de la terre

Lorsqu'elles sont conçues avec une protection appropriée contre la corrosion, les parois en clous de sol sont efficaces en tant que structures de retenue permanentes pour :

- Pentes des autoroutes et des voies ferrées

- Culées de pont

- Stabilisation des glissements de terrain

- Soutien des pentes instables existantes

Les applications permanentes nécessitent des approches de conception plus conservatrices et des systèmes de protection contre la corrosion améliorés pour garantir des performances à long terme.

Réparation et réhabilitation

Le clouage du sol constitue une solution efficace pour la stabilisation des pentes défaillantes existantes et réparation des structures de soutènement détériorées. La technique peut souvent être mise en œuvre sans démontage complet de la structure existante, ce qui minimise les perturbations et les coûts.

Systèmes composites

De plus en plus, les clous de sol sont combinés à d'autres techniques de stabilisation pour créer systèmes hybrides qui exploitent les avantages de plusieurs technologies. Les combinaisons les plus courantes sont les suivantes

- Clous de sol avec pieux de soldat: Augmente la rigidité pour contrôler les déformations

- Clous de sol avec ancres de terre précontraintes: Offre une plus grande résistance aux mouvements latéraux

- Clous de sol avec murs MSE: Crée des structures de transition efficaces entre les sections de coupe et de remplissage

Ces systèmes composites permettent d'étendre l'application du clouage de sol à des conditions de sol plus difficiles et à des charges plus élevées que celles qu'il serait possible d'obtenir avec des clous de sol seuls.

Analyse comparative : Murs de clous contre d'autres systèmes de rétention

Il est essentiel de comprendre comment les parois cloutées se comparent aux autres systèmes de rétention de terre pour effectuer un choix technique approprié. Le tableau suivant résume les principales différences :

Tableau : Comparaison des murs de clous avec d'autres systèmes de rétention de la terre

| Paramètres | Murs de clous de terre | Murs MSE | Pile de soldat et calage | Murs en porte-à-faux |

|---|---|---|---|---|

| Gamme de hauteurs typiques | Jusqu'à 15 m | Jusqu'à 15 m et plus | Jusqu'à 15 m | Jusqu'à 6 m |

| Coût relatif | Faible | Moyen | Moyenne-élevée | Haut |

| Vitesse de construction | Rapide | Moyen | Moyen | Lenteur |

| Exigences en matière d'espace | Significatif derrière le mur | Minimal derrière le mur | Diverses mesures peuvent nécessiter un décalage | Une fondation importante |

| Déformation | Petite à moyenne | Petit | Moyen | Très petit |

| Options esthétiques | Limitée | Très large | Limitée | Très large |

| Conditions idéales du sol | Cohésion, capacité de résistance | Remplissage granulaire | Divers, peut nécessiter un décalage | Une base stable |

| Performance sismique | Excellent | Bon | Juste | Bon |

Cette comparaison met en évidence le créneau dans lequel les parois clouées au sol excellent : la construction rapide et rentable de structures de soutènement de hauteur moyenne dans des sites où l'espace est limité et où les conditions de sol sont appropriées.

Tendances et développements futurs dans la technologie du clouage des sols

Contrôle et instrumentation avancés

L'avenir du clouage des sols passe par une mise en œuvre accrue des éléments suivants capteurs intégrés et systèmes de télésurveillance qui fournissent des données de performance en temps réel pendant et après la construction. Ces technologies permettent :

- Vérification des performances: Confirmation que la structure se comporte comme prévu

- Alerte précoce: Détecter les problèmes potentiels avant qu'ils ne deviennent critiques

- Surveillance de la santé à long terme: Particulièrement utile pour les installations permanentes

Les capteurs à fibre optique, la transmission de données sans fil et les systèmes d'alerte automatisés rendent la surveillance continue plus abordable et plus accessible.

Systèmes améliorés de protection contre la corrosion

La recherche continue à se développer protection renforcée contre la corrosion qui prolongent la durée de vie des installations permanentes de clous de sol tout en conservant un bon rapport coût-efficacité. Les innovations comprennent :

- Double barrière anticorrosion des systèmes avec des matériaux améliorés

- Protection cathodique intégré aux clous du sol

- Matériaux non corrosifsy compris les polymères renforcés par des fibres (PRF)

Ces développements sont d'autant plus importants que les agences de transport spécifient de plus en plus souvent des durées de vie de 100 ans pour les structures permanentes de rétention de terre.

Systèmes composites et hybrides

La tendance à la la combinaison du clouage du sol avec d'autres techniques de stabilisation continue de repousser les limites d'application de la technologie. Parmi les innovations récentes, on peut citer

- Clouage du sol à l'aide de micropieux pour les sols difficiles

- Clouage du sol avec stabilisation biotechnique pour une meilleure intégration de l'environnement

- Clouage du sol avec des systèmes de drainage avancés pour les conditions difficiles des eaux souterraines

Ces approches hybrides tirent parti des atouts de plusieurs technologies pour relever des défis géotechniques complexes.

Raffinements de la méthodologie de conception

Les recherches en cours permettent d'affiner les méthodes de conception pour répondre aux besoins :

- Amélioration de la prédiction de la déformation grâce à une modélisation numérique avancée

- Conception basée sur les performances des approches axées sur les exigences en matière d'aptitude au service

- Conception basée sur la fiabilité l'intégration de l'évaluation quantitative des risques

- Conception sismique des améliorations fondées sur les résultats obtenus lors de récents tremblements de terre

Ces progrès méthodologiques rendent la conception des parois cloutées plus prédictive et plus fiable.

Conclusion

Murs de clouage du sol représentent une solution sophistiquée et pratique à de nombreux défis géotechniques modernes. Leur rentabilité, l'adaptabilité aux sites contraignants, construction rapideet une performance prouvée en font une technique inestimable dans la boîte à outils de l'ingénieur civil. Alors que le secteur de la construction est confronté à une pression croissante pour fournir des infrastructures de manière plus efficace, plus durable et plus économique, les avantages du clouage de sol deviennent de plus en plus significatifs.

Bien que le clouage de sol ne convienne pas à toutes les situations - il faut respecter ses limites dans les sols très mous, les conditions de nappe phréatique élevée et les applications exigeant une déformation minimale - lorsqu'il est appliqué judicieusement par des professionnels expérimentés, il offre une valeur et des performances exceptionnelles.

L'avenir du clouage de sol est prometteur, avec des progrès constants dans les matériaux, les technologies de surveillance, les méthodologies de conception et les systèmes hybrides qui élargissent continuellement ses applications et améliorent sa fiabilité. Nous continuons à construire et à entretenir nos infrastructures dans un environnement de plus en plus difficile, murs de clouage du sol joueront sans aucun doute un rôle crucial dans l'élaboration du paysage construit de demain.

Pour les ingénieurs, les entrepreneurs et les maîtres d'ouvrage confrontés à des défis de rétention de terre, le clouage de sol Ame Drill mérite d'être considéré sérieusement comme une solution techniquement solide et économiquement avantageuse qui a résisté à l'épreuve du temps tout en continuant d'évoluer avec les exigences de la construction moderne.