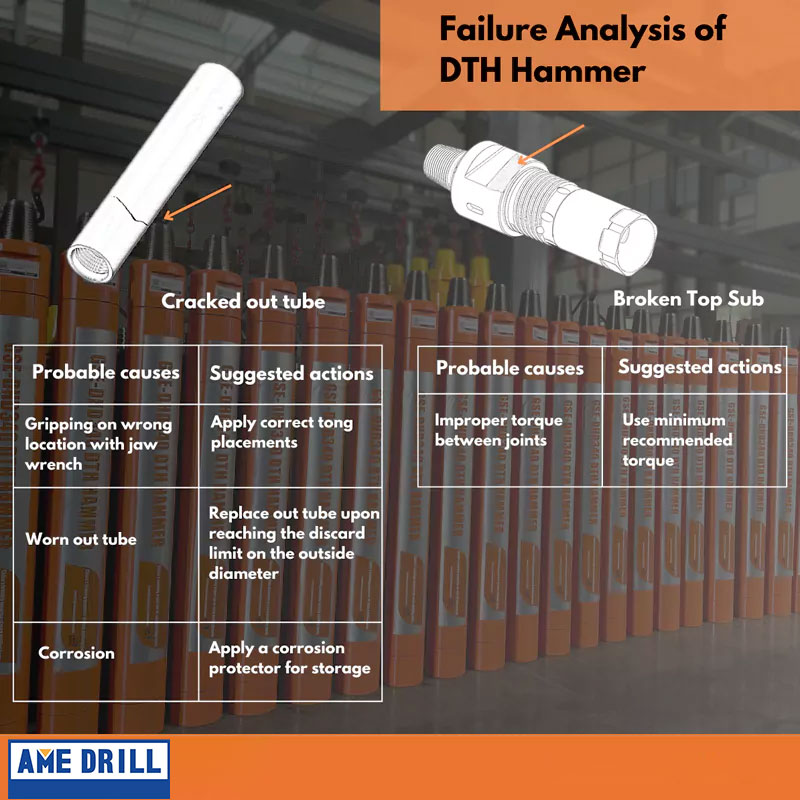

1. Sous-entraînement cassé

Causes probables :

- Espace entre l'épaulement du sous-groupe d'entraînement et le tube de sortie

- L'articulation est lâche

- Pression d'alimentation insuffisante

- Filets non lubrifiés

Actions suggérées :

- Appliquer le couple de serrage approprié

- Amélioration de la force d'alimentation dans des conditions de roches tendres et non consolidées

- Assurer une pression d'alimentation suffisante

- Remplacer le sous-système d'entraînement

- Utiliser le type et la quantité de graisse appropriés pour les filets de l'entraînement.

2. Sous-entraînement fissuré

Causes probables :

- Mauvaise manipulation d'une masse

Actions suggérées :

- Utiliser des pinces ou des chaînes pour détacher le sous-marin d'entraînement du tube de sortie.

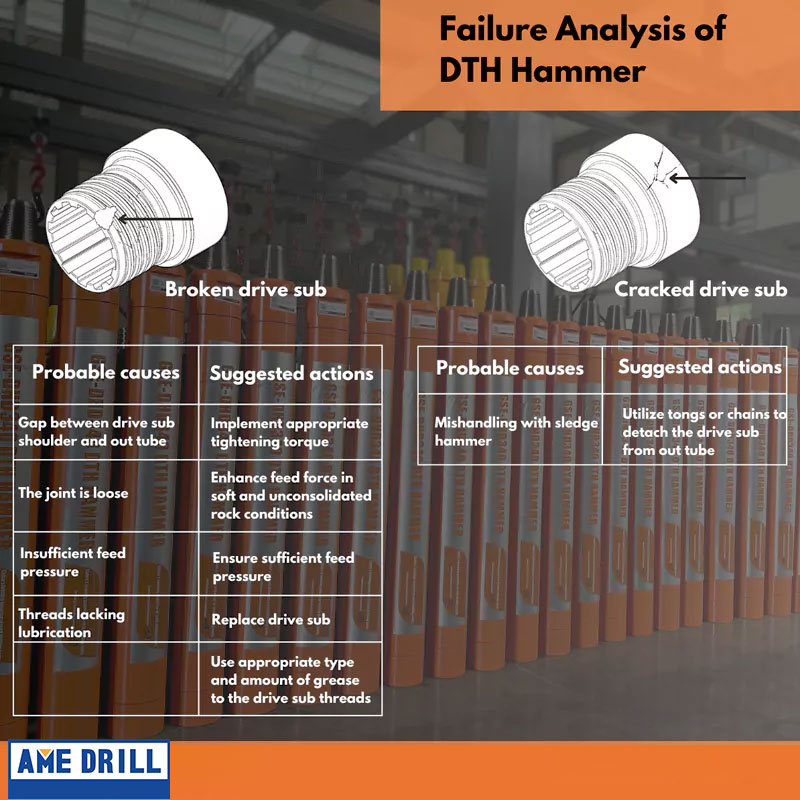

3. Piston cassé

Causes probables :

- Galling

- Corrosion au niveau de la contre-dépouille du piston

Actions suggérées :

- Nettoyer le marteau avec de la mousse après le perçage

- Vérifier régulièrement la lubrification ; utiliser le bon type et la bonne quantité d'huile pour marteaux.

4. Piston fissuré

Causes probables :

- Emplacement incorrect de la clé

- Lubrification insuffisante

- Coincé dans le trou

- Déviation du trou

Actions suggérées :

- Inspecter le système de lubrification et s'assurer qu'un film d'huile se forme dans les trous de rinçage du trépan.

- Utiliser des zones de serrage pour éviter toute déformation du tube de sortie.

- Utiliser de l'eau en cas de blocage car le frottement peut provoquer des déformations.

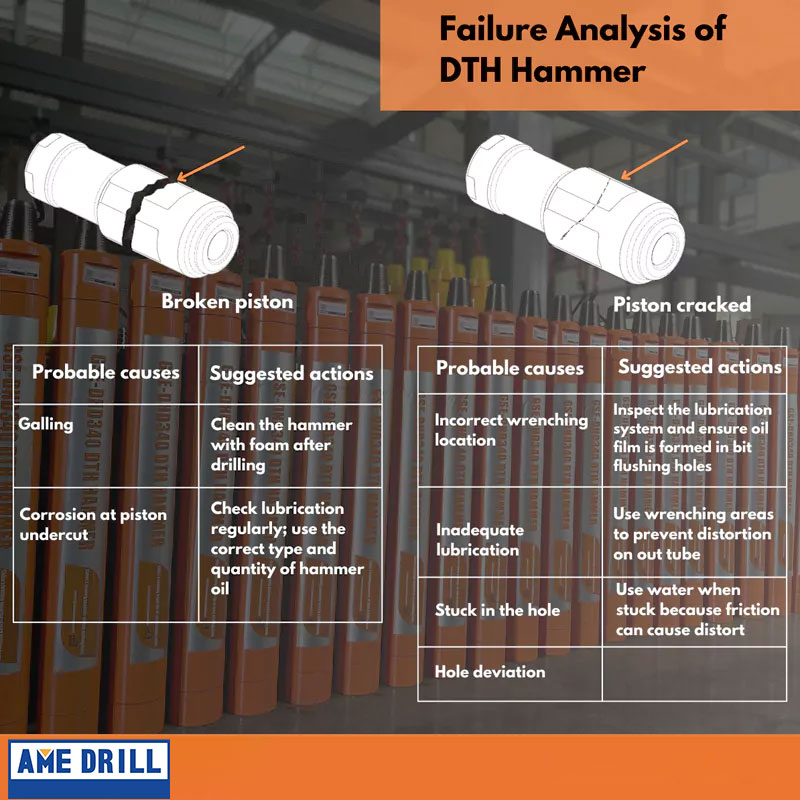

5. Tube fissuré

Causes probables :

- Saisir au mauvais endroit avec une clé à mâchoires

- Tube usé

- Corrosion

Actions suggérées :

- Appliquer le placement correct de la langue

- Remplacer le tube lorsqu'il atteint la limite de rejet du diamètre extérieur.

- Appliquer un protecteur anticorrosion pour le stockage

6. Broken Top Sub

Causes probables :

- Couple inadéquat entre les joints

Actions suggérées :

- Utiliser le couple minimum recommandé