Introduction

Lorsqu'il s'agit de forer dans des roches dures, peu de technologies se sont avérées aussi efficaces que le système de forage à l'explosif. Le marteau du fond du trou. Contrairement aux foreuses à percussion par le haut, où l'énergie d'impact doit se déplacer le long du train de tiges (perdant ainsi une grande partie de sa force), un marteau DTH place le mécanisme de percussion juste derrière le trépan. Il en résulte une plus grande efficacité, des trous plus droits et un meilleur transfert d'énergie.

Dans cet article, nous allons nous pencher sur les points suivants comment fonctionne un marteau de fond de trouVous y découvrirez ses composants, ses principes de fonctionnement, ses avantages en termes de performances et ses applications pratiques. À la fin, vous comprendrez non seulement la théorie, mais aussi la valeur technique qu'elle apporte à l'exploitation minière, à la construction et au forage de puits d'eau.

Produits recommandés

Brève histoire de la technologie DTH

L'idée de placer le mécanisme de percussion au fond a été lancée au début des années 1950. Les premières inventions ont été réalisées par des entreprises telles que Stenuick Frères et Ingersoll Randqui, indépendamment, a introduit les marteaux pneumatiques de fond de trou.

Depuis lors, la technologie a considérablement évolué :

- Marteaux pneumatiques DTH est devenu la norme mondiale pour l'exploitation minière et la construction.

- Marteaux à eau ont été introduits par la suite pour minimiser la poussière et le bruit et améliorer les performances environnementales.

- Marteaux à boue est apparu comme une solution pour le forage de pétrole et de gaz dans des formations instables ou soumises à une pression excessive.

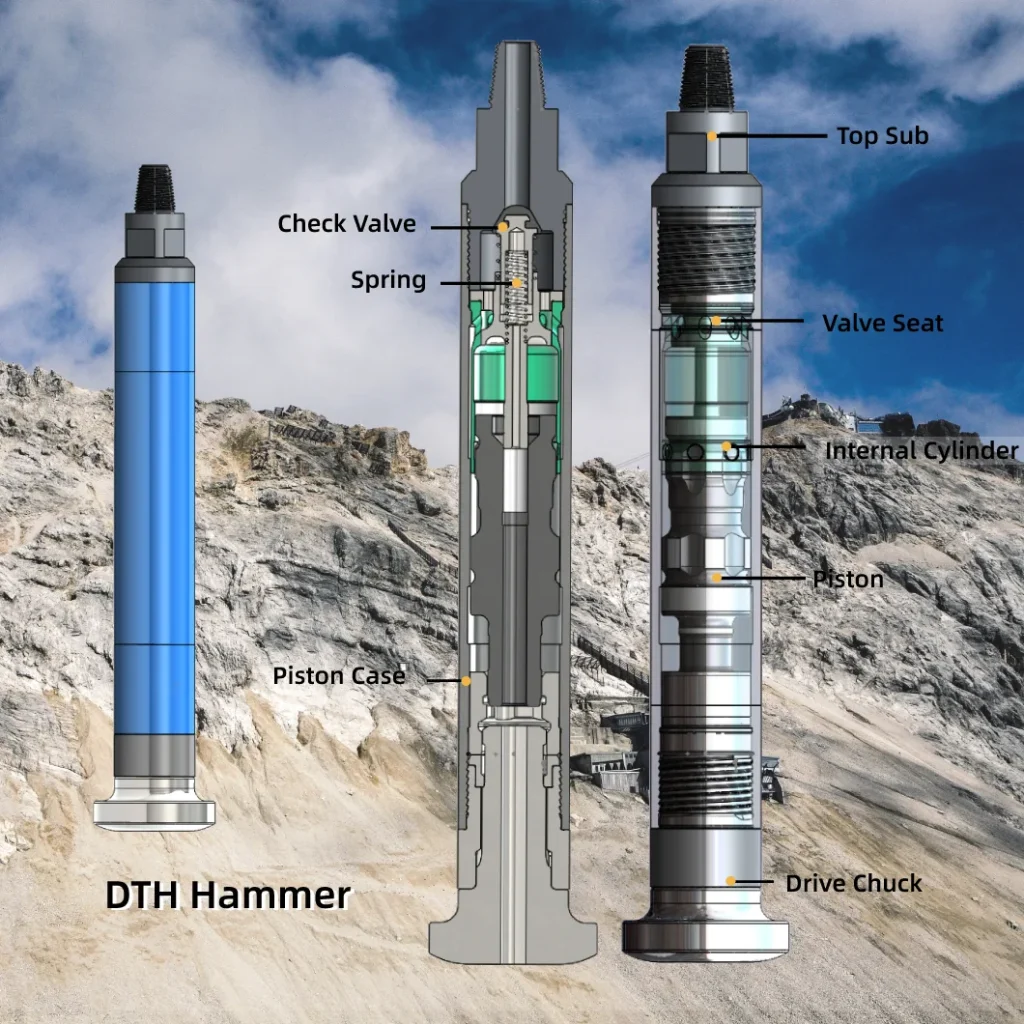

Anatomie d'un marteau DTH

À la base, un Marteau DTH est un système de percussion compact et robuste situé juste au-dessus du trépan. Ses principaux composants sont les suivants :

- Corps du marteau - Le boîtier cylindrique qui contient le piston et guide le mécanisme d'impact.

- Piston - Un composant lourd, à mouvement rapide, qui frappe directement le trépan.

- Valve / Distributeur d'air - Contrôle le débit d'air comprimé (ou d'eau/boue), en veillant à ce que le piston monte et descende au cours d'un cycle.

- Foret - L'élément de coupe (souvent avec des boutons en carbure de tungstène) qui fracture la roche.

- Adaptateur de queue / Mandrin - Transfère l'énergie du marteau dans l'embout tout en permettant le remplacement de l'embout.

- Passages d'air / canaux de rinçage - Transporter de l'air comprimé ou un fluide pour retirer les débris de roche du trou de forage.

📷 [Insérer le schéma du marteau DTH montrant le piston, la valve, le trépan et le cycle d'écoulement de l'air].

Le principe de fonctionnement - étape par étape

La magie du marteau DTH réside dans son mécanisme de piston alternatifLes machines à coudre sont des machines à coudre à air comprimé (ou parfois à l'eau).

- Approvisionnement en énergie - L'air à haute pression provenant d'un compresseur est dirigé vers le bas du train de tiges dans le marteau.

- Distribution d'air - Le mécanisme de la valve canalise l'air pour pousser alternativement le piston vers le bas et le remonter.

- Action du piston - Le piston frappe la tige du trépan à une fréquence élevée (jusqu'à 2 500 coups par minute).

- Transfert d'impact - Chaque coup transfère l'énergie directement dans le trépan, qui fracture la roche sous-jacente.

- Rotation et alimentation - Simultanément, le train de tiges tourne, assurant une coupe uniforme et la rectitude du trou.

- Enlèvement des boutures - L'air d'échappement sort par des trous dans le trépan, ce qui permet de faire remonter à la surface les éclats de roches concassées.

Ce cycle continu assure une pénétration efficace de la roche avec une perte d'énergie minimale par rapport aux systèmes à marteau supérieur.

Caractéristiques techniques

Les marteaux DTH sont conçus pour être performants dans différentes conditions de roche. Vous trouverez ci-dessous une comparaison des paramètres de performance typiques :

| Paramètres | Marteau DTH | Perceuse à percussion supérieure |

|---|---|---|

| Transfert d'énergie par impact | ~95% (direct) | 50-60% (perte de tiges) |

| Adéquation de la profondeur de forage | 50-6 000 ft | < 200 ft |

| Rectitude du trou | Haut | Moyen |

| Fréquence de soufflage typique | 1 500-2 500 bpm | 2 000-3 000 bpm |

| Diamètres de trous appropriés | 3" - 48" | 1" - 6" |

Tableau 1 : Comparaison des performances entre les systèmes DTH et top-hammer.

Avantages des marteaux fond de trou

- Transfert d'énergie efficace - Comme le marteau se trouve en bas, la quasi-totalité de l'énergie de l'impact va dans le trépan.

- Excellente rectitude des trous - La réduction des forces de flexion se traduit par des trous plus droits et plus précis.

- Capacité de forage en profondeur - Capable de forer à des centaines, voire des milliers de pieds de profondeur.

- Productivité élevée dans les roches dures - Il donne des résultats exceptionnels dans le granit, le basalte et d'autres formations coriaces.

- Polyvalence - Travaille dans les mines, les carrières, les puits d'eau, la géothermie et la construction de fondations.

Limites et défis

Malgré ses avantages, le forage DTH n'est pas parfait :

- Dépendance à l'égard de l'approvisionnement en air - Nécessite de gros compresseurs, ce qui augmente les coûts d'exploitation.

- Usure de l'embout - Les boutons et les tiges de mèches en carbure s'usent plus rapidement dans les formations abrasives.

- Bruit et poussière - Les marteaux pneumatiques produisent des niveaux de bruit élevés ; pour les atténuer, il faut injecter de l'eau ou installer des silencieux.

- Efficacité sur sol meuble - Moins efficace dans les sols non consolidés ou les formations meubles.

Champs d'application

Les marteaux DTH sont largement utilisés dans toutes les industries :

- Mines et carrières - Forage de trous de mine pour une fragmentation efficace de la roche.

- Puits d'eau et géothermie - Perçage d'alésages droits et profonds avec une déviation minimale.

- Construction et fondations - Installation de douilles en pierre, de micropieux et d'ancrages au sol.

- Exploration pétrolière et gazière - Marteaux spécialisés à boue pour les formations profondes et surpressées.

- Construction urbaine - Marteaux hydrauliques à basse pression pour les environnements sensibles aux vibrations.

Considérations techniques pour la sélection

Lorsqu'ils choisissent un marteau fond de trou pour un projet, les ingénieurs doivent tenir compte des éléments suivants :

- Capacité du compresseur (pression d'air et débit volumétrique).

- Exigences relatives à la taille des trous (généralement de 3 à 48 pouces).

- Conditions géologiques (dureté, abrasivité, fractures).

- Conception des bits (boutons plats, concaves, convexes, balistiques).

- Coûts opérationnels (durée de vie du bit, consommation de carburant, taille du compresseur).

Tendances futures de la technologie DTH

L'industrie des marteaux DTH s'oriente vers.. :

- Marteaux actionnés par l'eau (écologique, sans poussière et plus silencieux).

- Marteaux hybrides combinant les modes rotatif et percussion.

- Systèmes de forage intelligents avec des capteurs pour le contrôle des performances en temps réel.

- Matériaux avancés pour une meilleure résistance à l'usure et une plus longue durée de vie de la mèche.

- Conceptions à faible émission de carbone qui réduisent la consommation de carburant du compresseur.

Conclusion

Le marteau de fond de trou est l'une des technologies de forage les plus efficaces pour les applications dans les roches dures et les trous profonds. En plaçant le mécanisme de percussion directement derrière le trépan, il maximise l'énergie de l'impact, améliore la rectitude du trou et permet de forer plus profondément.

Bien que des défis tels que les besoins en compresseurs et l'usure des trépans subsistent, des innovations telles que les marteaux hydrauliques et les technologies de forage intelligentes continuent d'élargir leur potentiel.

Pour les ingénieurs et les foreurs, comprendre Comment fonctionne un marteau DTH est essentielle pour optimiser les opérations de forage, réduire les coûts et garantir des performances sûres et efficaces.

Bienvenue chez Ame Drill, fabricant d'outils de forage de roches et de consommables de forage.