Dans les opérations de forage modernes - qu'il s'agisse de l'exploitation minière, de la construction ou de l'exploration géologique -, l'eau est un élément essentiel.tiges de forage jouent un rôle essentiel. Ils constituent le lien entre le trépan et la machine de forage, et sont responsables de la transmission du couple, de l'énergie d'impact et du fluide de rinçage en profondeur dans la terre.

Cependant, le terme "tige de forage" a une signification différente. double sens. Dans le domaine du forage industriel, il s'agit d'une longue tige d'acier tubulaire utilisée pour augmenter la profondeur du forage. Dans le domaine de la métallurgie et de l'outillage, il désigne tiges en acier à outils rectifiées avec précision utilisé pour la fabrication de forets, de poinçons et de matrices.

Dans cet article, nous allons nous pencher sur les points suivants Applications des tiges de forageCette brochure explique comment ils sont fabriqués, quels sont leurs principaux types, où ils sont utilisés et ce qui les rend indispensables dans de nombreux secteurs d'activité.

1. Qu'est-ce qu'une tige de forage ?

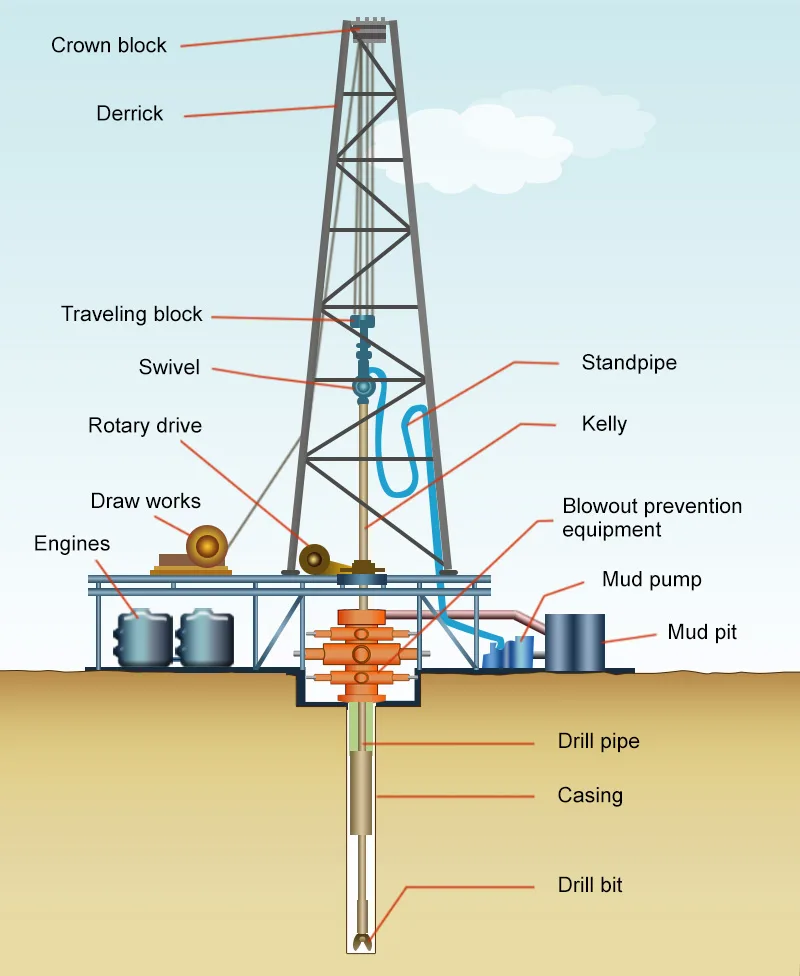

A tige de forage est une barre d'acier cylindrique conçue pour relier le trépan à la source d'énergie, transmettant à la fois le mouvement de rotation et l'énergie de percussion. Dans les systèmes de forage au marteau-pilon, l'impact est transféré du marteau au trépan par l'intermédiaire de la tige. Dans les systèmes de forage au fond du trou (DTH), la tige de forage (ou le tube) sert de passage d'air qui fournit de l'air comprimé directement au marteau DTH.

Dans le domaine de la fabrication d'outils, le terme "tige de forage" désigne stock d'acier à outils-Les barres hautement polies et rectifiées avec précision sont fabriquées à partir d'aciers à haute teneur en carbone ou d'aciers alliés. Ces barres constituent le matériau de base pour la fabrication de forets, de tarauds, d'alésoirs, de poinçons, de matrices et de divers outils de coupe.

2. Composition des matériaux et traitement thermique

Les tiges de forage sont généralement fabriquées à partir de aciers alliés de haute qualitéLe choix de l'acier dépend de l'environnement de forage prévu et des contraintes mécaniques. Le choix de l'acier dépend de l'environnement de forage prévu et des contraintes mécaniques.

Les processus de fabrication comprend généralement

- Le laminage à chaud de la barre au diamètre désiré.

- Redressement et usinage de la surface de la tige.

- Meulage et polissage de précision pour l'exactitude des dimensions.

- Traitement thermique (trempe et revenu) pour obtenir une résistance et une ténacité élevées.

Types de tiges de forage par méthode de durcissement

(Adapté des données des supermarchés Metal)

| Type | Moyen de refroidissement | Caractéristiques principales | Applications typiques |

|---|---|---|---|

| Durcissement à l'eau (W) | L'eau | Économique, facile à usiner | Outils à main, limes, ciseaux |

| Durcissement à l'huile (O) | Huile | Ténacité élevée, bonne résistance à l'usure | Poinçons, matrices, mèches |

| Durcissement à l'air (A) | Air | Grande stabilité dimensionnelle, grande dureté | Outils de précision, matrices de découpe |

Une trempe appropriée garantit que la tige de forage peut résister à une torsion intense, à une charge axiale et à des vibrations sans se plier ni se fracturer, un facteur critique dans les applications exigeantes de l'industrie de l'acier. applications de forage.

3. Types de tiges de forage utilisées dans les systèmes de forage

Toutes les tiges de forage ne sont pas identiques. Chaque type est conçu pour des conditions et des méthodes de forage spécifiques.

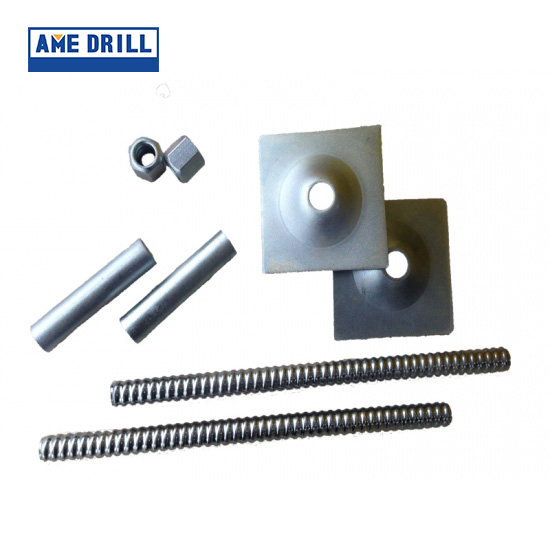

1. Tiges de forage coniques

Utilisé principalement pour le forage de petits trous dans la roche, l'exploitation de carrières et le traitement de la pierre. La conception conique permet un remplacement rapide du trépan et un transfert d'énergie en douceur.

2. Tiges filetées ou rallonges

Courant dans les mines, les tunnels et les opérations de forage en profondeur. Les tiges filetées sont reliées bout à bout à l'aide de raccords, formant un long train de forage qui peut pénétrer à plusieurs centaines de mètres.

3. Tiges MF (mâle-femelle)

Ces tiges comportent une extrémité filetée mâle et une extrémité filetée femelle, ce qui élimine la nécessité d'utiliser des raccords séparés. Il en résulte une perte d'énergie moindre, une manipulation plus aisée et des cycles de forage plus rapides.

4. Tiges de forage intégrées

Forgées en une seule pièce avec le trépan, ces tiges sont idéales pour les perforateurs portatifs dans la construction et les carrières, car elles offrent une fiabilité et une portabilité excellentes.

5. Tubes de forage DTH

En Au fond du trou (DTH) Lors du forage, ces tuyaux fournissent de l'air comprimé pour alimenter le marteau au fond du trou. L'air permet également d'évacuer les éclats de roche vers le haut.

Idée d'illustration : Un diagramme étiqueté montrant un train de tiges de forage DTH - appareil de forage → tige de forage → marteau → trépan - permettrait de clarifier visuellement ces relations.

4. Principales applications des tiges de forage

Les applications des tiges de forage sont vastes, allant de l'exploitation minière et de la construction à la fabrication d'outils de précision. Voici les principaux secteurs où les tiges de forage sont indispensables.

A. Mines et carrières

Les tiges de forage sont essentielles pour les opérations de forage, de creusement de tunnels et de dynamitage. Dans les mines à ciel ouvert et souterraines, elles transmettent l'énergie d'impact des foreuses de roche au trépan, brisant ainsi les formations rocheuses dures.

Des fabricants comme BestoneDrill et SinoDrills fournit des tiges d'extension et des tiges MF conçues pour une grande résistance aux chocs, une longue durée de vie et des performances de rinçage efficaces dans des conditions de roches abrasives.

B. Forages géologiques et d'exploration

Pour la prospection minière et l'échantillonnage de carottes, les tiges de forage relient le trépan, le carottier et l'appareil de forage. Elles doivent résister à la flexion et à la torsion tout en maintenant une étanchéité parfaite pour une récupération précise des carottes.

C. Forage de puits d'eau et de fondations

Les tiges filetées longues ou les tubes DTH sont utilisés pour le forage de puits profonds, de systèmes géothermiques et de pieux de fondation. Ces tiges assurent un alignement précis et une bonne circulation de l'air dans les trous profonds.

D. Construction et génie civil

Dans les travaux de génie civil, les tiges de forage sont utilisées pour l'ancrage des roches, la stabilisation des pentes et les micropieux. Leur durabilité permet des performances fiables dans les systèmes de forage rotatif et à percussion.

E. Outillage et fabrication

Comme le souligne Supermarchés du métalLes tiges de forage de qualité outil sont essentielles à la fabrication d'outils tels que les alésoirs, les poinçons, les goujons, les arbres et les matrices de coupe.

5. Avantages de l'utilisation de tiges de forage de haute qualité

Selon le LitechTools et Outils de forage THLes tiges de forage de qualité supérieure présentent de nombreux avantages opérationnels et économiques :

- Durabilité accrue : Fabriqué en acier à haute résistance, capable de supporter des chocs et des torsions intenses.

- Transfert d'énergie cohérent : Les filets usinés avec précision garantissent une perte d'énergie minimale entre les joints.

- Facilité d'entretien : La conception modulaire permet de remplacer facilement les sections usées.

- Réduction des temps d'arrêt : Une meilleure résistance à la fatigue prolonge la durée de vie, réduisant ainsi les coûts globaux de forage.

- Amélioration de la sécurité : L'intégrité structurelle élevée empêche les ruptures sous contrainte, ce qui réduit les risques opérationnels.

6. Choisir la bonne tige de forage

Le choix de la tige de forage appropriée dépend du type d'opération de forage, des conditions géologiques et de la configuration de l'équipement.

| Application | Type recommandé | Matériau | Propriété principale |

|---|---|---|---|

| Exploitation minière à ciel ouvert | Rallonge ou tige MF | 35CrMo | Résistance élevée à la traction |

| Exploitation de carrières | Tige conique | 45CrNiMo | Léger et résistant aux chocs |

| Forage DTH | Tube DTH | Acier allié | Flux d'air à haute pression |

| Forage d'exploration | Tige filetée | 42CrMo4 | Capacité de couple élevée |

| Fabrication d'outils | Tige trempée à l'huile | Acier O1 / A2 | Usinage de précision |

Lors de votre choix, tenez compte des éléments suivants :

- Les méthode de forage (marteau supérieur, rotatif ou DTH).

- Dureté et abrasivité des roches.

- Profondeur de forage et taille du trépan.

- Compatibilité des type de filetage et système de couplage.

7. Maintenance et bonnes pratiques

Un entretien adéquat des tiges de forage garantit une durée de vie plus longue et des performances constantes :

- Lubrifier les filetages avant et après chaque utilisation pour éviter le grippage.

- Vérifier l'absence de fissures ou l'usure après chaque cycle de forage.

- Éviter le serrage excessifqui peuvent endommager les filetages ou provoquer des ruptures.

- Stocker les tiges horizontalement dans des conditions sèches afin d'éviter toute déformation ou corrosion.

- Remplacer rapidement les parties endommagées afin d'éviter toute perte d'énergie ou toute défaillance de l'outil.

8. Innovations et tendances futures

Les industrie des tiges de forage évolue avec de nouveaux matériaux et de nouvelles technologies visant à améliorer l'efficacité et la durabilité :

- Alliages légers à haute résistance (comme les aciers mélangés au titane) réduisent la consommation d'énergie.

- Raccords soudés par friction améliorer la durée de vie des filets et minimiser les vibrations.

- Revêtements avancés (nickel, zinc ou céramique) offrent une meilleure résistance à la corrosion et à l'usure.

- Systèmes de forage intelligents intègrent désormais des capteurs pour surveiller les contraintes, la température et l'usure en temps réel, ce qui permet d'optimiser les programmes de maintenance.

Des fabricants comme SinoDrills, BestoneDrillet Terraroc Drilling continuent d'innover en améliorant la métallurgie, le traitement thermique et les techniques d'usinage afin de répondre à la demande mondiale en matière de forage.

9. Conclusion

Dans le monde du forage et de la fabrication d'outils, les tiges de forage sont l'épine dorsale de la performance et de la fiabilité. Qu'il s'agisse de transmettre l'énergie dans les profondeurs des mines ou de former le matériau de base des outils de précision, leurs applications sont diverses et essentielles.

Investir dans des tiges de forage de haute qualité - fabriquées avec des aciers avancés, des tolérances serrées et des systèmes de filetage durables - garantit un meilleur transfert d'énergie, une durée de vie plus longue et une plus grande efficacité opérationnelle.

Comprendre Applications des tiges de forage permet non seulement de choisir l'outil adéquat pour le travail à effectuer, mais aussi de stimuler la productivité, la sécurité et le retour sur investissement dans toute opération de forage.

Bienvenue sur le site d'AME Drill pour commander des tiges de forage.