Les 7 étapes de la procédure de forage Le processus d'extraction du pétrole et du gaz naturel du sous-sol est une opération complexe, qui nécessite beaucoup d'ingénierie. Aux États-Unis, où le secteur de l'énergie est l'un des piliers de l'économie, il est essentiel de comprendre ce processus. Il s'agit d'une séquence d'étapes méticuleusement planifiées, conçues pour atteindre les réserves d'hydrocarbures de manière sûre et efficace. Si les spécificités peuvent varier en fonction de la géologie, de la technologie et de la nature de l'opération (onshore ou offshore), la procédure fondamentale reste la même. Ce guide complet décompose les sept étapes essentielles de la procédure de forage, offrant une vue d'ensemble claire de la manière dont les ressources sont acheminées du réservoir à la surface.

Étape 1 : Préparation du site de la plate-forme

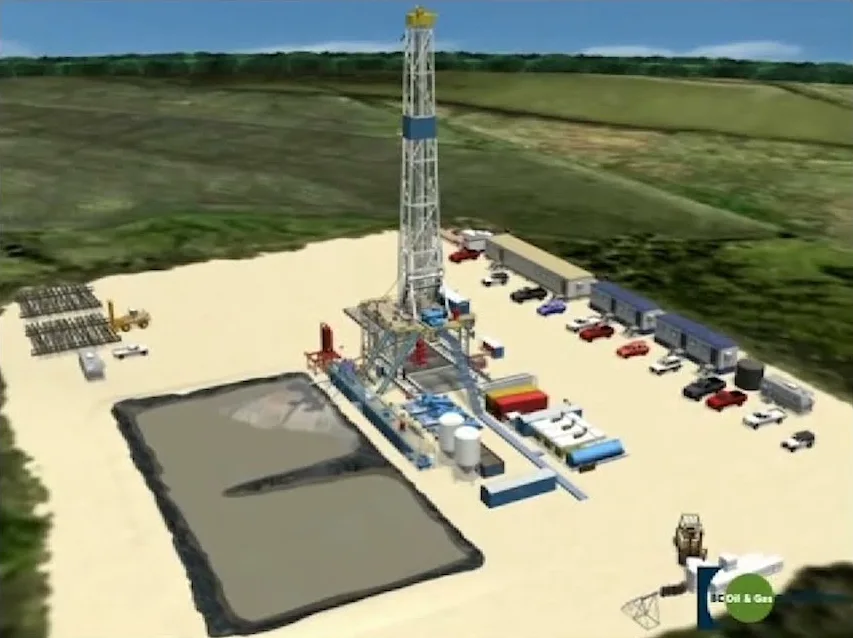

Avant qu'un trépan ne touche le sol, une planification et une préparation approfondies sont nécessaires. Cette première étape est essentielle pour garantir la sécurité et la protection de l'environnement. Le processus commence par étude sismique pour cartographier la géologie du sous-sol et identifier les réservoirs prometteurs. Une fois le site sélectionné, le terrain doit être déblayé et nivelé afin de créer une base stable pour la construction des réservoirs. appareil de forage et tous les équipements associés.

Pour les sites terrestres, cela implique la construction de routes d'accès, le creusement de systèmes de drainage et le revêtement d'une fosse de réserve - bien que les pratiques modernes utilisent souvent des systèmes en circuit fermé pour minimiser l'impact sur l'environnement. Le site est préparé à l'aide d'une fondation en béton, appelée caveCette phase comprend également l'obtention de tous les permis nécessaires et la réalisation d'études d'impact sur l'environnement, qui sont des processus rigoureux dans le paysage réglementaire américain. Cette phase implique également l'obtention de tous les permis nécessaires et la réalisation d'études d'impact sur l'environnement, qui sont des processus rigoureux dans le paysage réglementaire américain.

Étape 2 : Comprendre les composants de l'appareil de forage

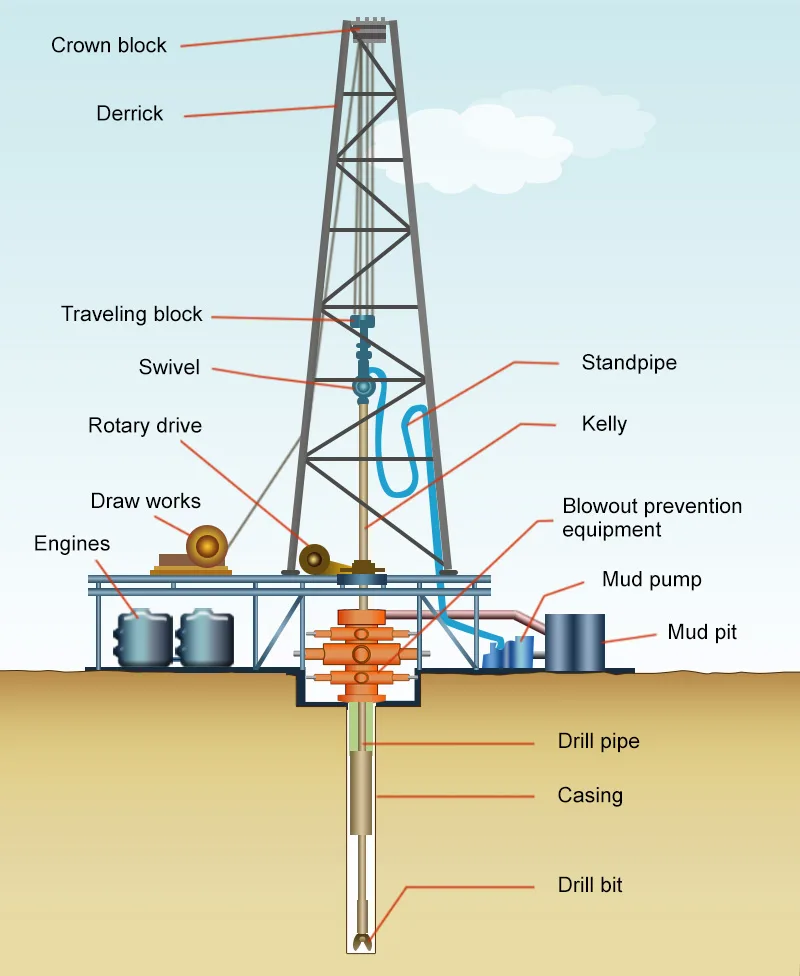

Une fois le site préparé, l'énorme appareil de forage et ses composants sont transportés et assemblés. Il s'agit d'une opération complexe en soi, car une plate-forme moderne est une pièce de machinerie complexe composée de plusieurs systèmes clés :

- Le Derrick : La structure haute, en forme de tour, qui fournit la hauteur nécessaire pour soulever et abaisser le train de tiges de forage.

- Le système de levage : Il s'agit des tiroirs, de la couronne et du bloc de déplacement, qui travaillent ensemble pour soulever la lourde tige de forage à l'intérieur et à l'extérieur du puits de forage.

- Le système rotatif : Composé d'une table rotative ou d'un entraînement supérieur, d'un kelly et d'un train de tiges, ce système fournit le couple nécessaire à la rotation du trépan.

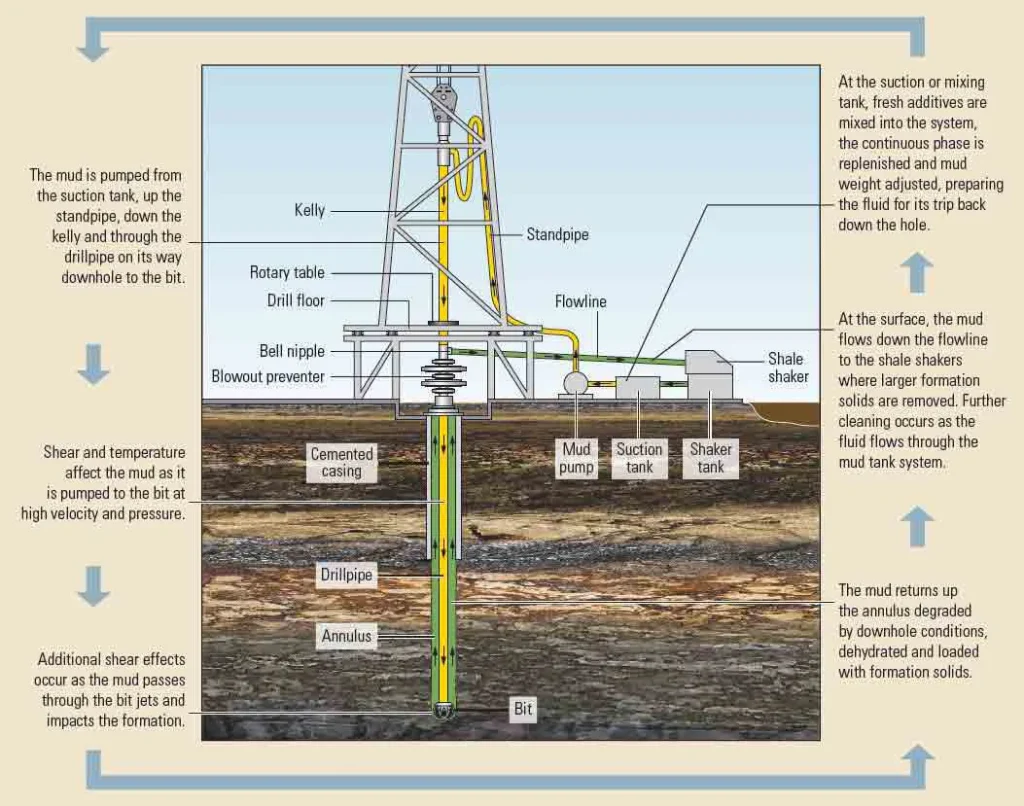

- Le système circulatoire : Pompes, tuyaux et fluide de forage (boue) qui font circuler le fluide le long du train de tiges et le font remonter dans l'espace annulaire.

- Le dispositif anti-éruption (BOP) : Un ensemble de vannes critiques installées sur la tête de puits pour contrôler la pression et empêcher la libération incontrôlée d'hydrocarbures (une éruption).

Comprendre ces appareil de forage composants est essentiel pour comprendre comment les étapes suivantes sont exécutées.

Produits recommandés

Étape 3 : Choix des techniques de forage

La stratégie globale permettant d'atteindre la profondeur cible consiste à choisir l'instrument de mesure approprié. techniques de forage. La méthode la plus courante est de loin la forage rotatif méthodequi utilise un trépan rotatif pour briser la roche. Cependant, dans ce cadre, plusieurs techniques sont employées :

- Forage directionnel : Il s'agit de forer des puits non verticaux. Il est utilisé pour atteindre des réservoirs situés directement sous des zones sensibles, pour accéder à une plus grande zone à partir d'une seule plateforme (réduisant ainsi l'empreinte en surface), ou pour opérations de forage en mer où plusieurs puits sont forés à partir d'une seule plate-forme.

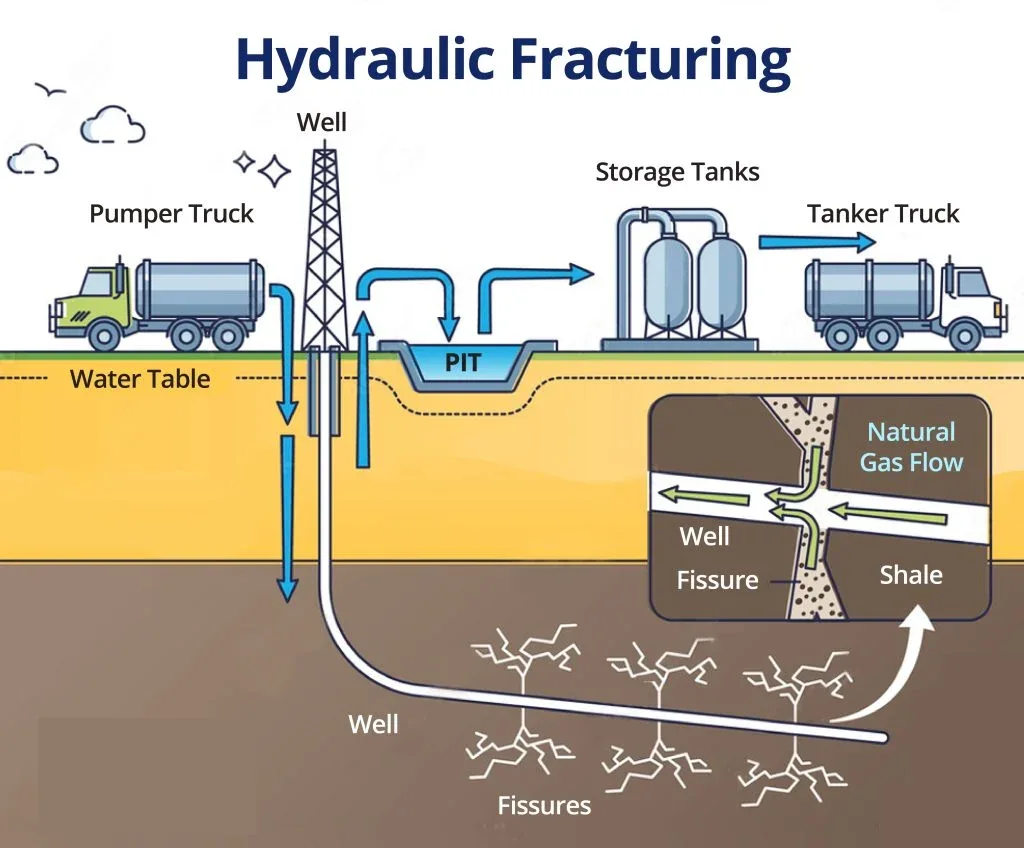

- Forage horizontal : Sous-ensemble du forage directionnel, cette technique consiste à forer un puits horizontalement dans la roche réservoir, ce qui augmente considérablement la zone de contact avec la formation porteuse de ressources. Il s'agit d'un élément clé pour l'exploitation des ressources naturelles. processus de fracturation hydraulique.

Le choix de la technique est une décision fondamentale qui a une incidence sur la conception et le coût de l'ensemble de l'opération.

Étape 4 : Mise en œuvre de la méthode de forage rotatif

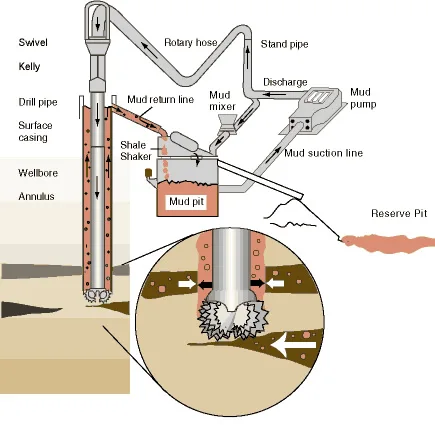

Cette étape est l'acte physique essentiel du forage. Les forage rotatif méthode commence par l'enfoncement dans le sol du trépan, fixé à des sections de tubes de forage. En faisant tourner le train de tiges, le trépan broie et écrase la roche. Simultanément, fluide de forage est pompé vers le bas à travers le train de tiges creux, sortant par des buses dans le trépan. Ce fluide remplit trois fonctions essentielles :

- Refroidissement et lubrification : Il refroidit le foret chaud et réduit la friction.

- Enlèvement des boutures : Il transporte les débris de roche concassée dans l'espace annulaire entre le train de tiges et la paroi du puits jusqu'à la surface.

- Stabilité du puits de forage : La densité du fluide crée une pression hydrostatique qui s'oppose aux pressions de la formation, empêchant les effondrements et les afflux de fluides dans le puits.

Au fur et à mesure que le forage progresse, de nouvelles sections de tiges de forage sont ajoutées au train de tiges. Ce processus se poursuit jusqu'à ce que la profondeur cible soit atteinte.

Étape 5 : Gestion des fluides de forage

Gestion des fluides de forage n'est pas une étape distincte, mais un processus intégral et continu tout au long de l'opération de forage. Le fluide de retour, qui contient maintenant des déblais, passe par des shale shakers (tamis vibrants) et d'autres équipements de contrôle des solides afin d'éliminer les particules de roche. Le fluide nettoyé est ensuite recirculé.

Les propriétés de la boue - son poids, sa viscosité et sa composition chimique - sont constamment contrôlées et ajustées par les ingénieurs spécialisés dans les boues. Il s'agit d'un aspect essentiel de la gestion des boues. l'optimisation des performances de forage et la sécurité. Une gestion appropriée garantit la stabilité du puits, contrôle les pressions souterraines, protège le réservoir contre les dommages et permet de recueillir des informations géologiques à partir des déblais.

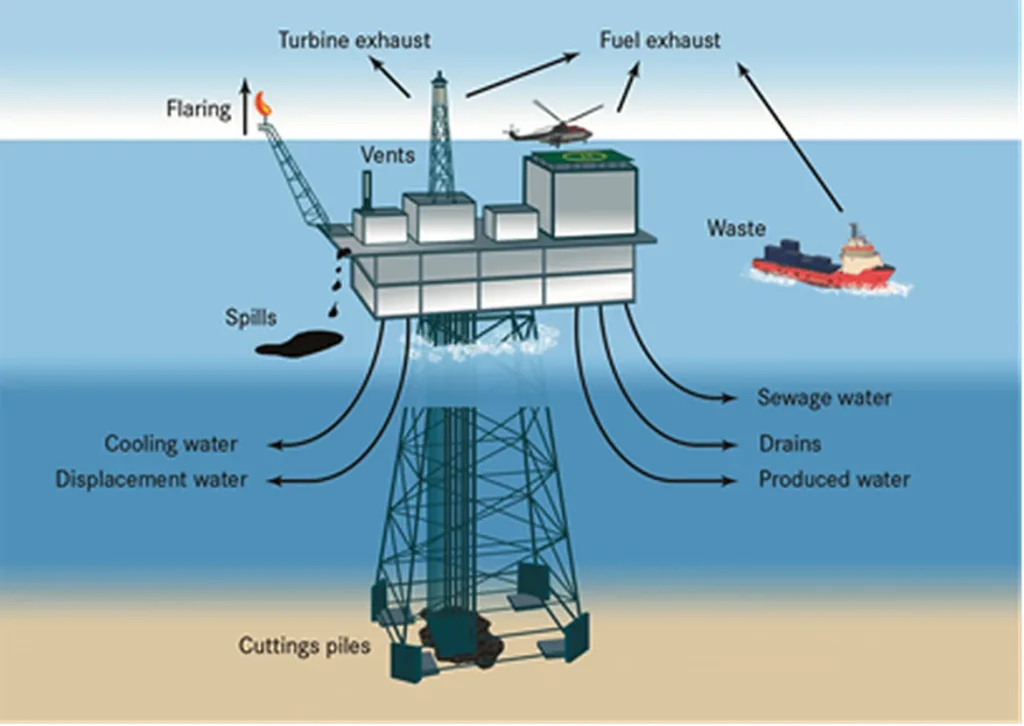

Étape 6 : Opérations de forage en mer

Opérations de forage en mer suivent les mêmes étapes fondamentales, mais avec une complexité considérablement accrue en raison de l'environnement marin. Au lieu d'un simple site préparé, les opérations nécessitent une plate-forme fixe, une plate-forme flottante ou un navire de forage. L'ensemble de la plate-forme doit être conçu pour résister aux vagues, aux courants et aux intempéries.

Un élément clé de différenciation est la colonne montante marine, un tuyau de grand diamètre qui relie la pile BOP sous-marine sur le plancher océanique à la plate-forme de forage. Elle guide le train de forage et fournit un conduit pour le retour du fluide de forage. Les défis de la logistique, de la sécurité de l'équipage et de la protection de l'environnement sont amplifiés, nécessitant une technologie avancée et des procédures opérationnelles rigoureuses.

Étape 7 : Processus de fracturation hydraulique

Il est important de noter que le processus de fracturation hydraulique n'est pas un élément standard de la procédure de forage de chaque puits. Il s'agit d'une technique de complétion distincte utilisée principalement dans les réservoirs non conventionnels tels que les roches de schiste. après le puits a été foré et tubé.

Une fois la profondeur cible atteinte, le train de tiges est retiré et un tubage en acier est inséré et cimenté dans le puits de forage afin d'en garantir l'intégrité. Lors d'une opération de fracturation hydraulique, un perforateur est ensuite descendu dans la zone cible pour créer des trous dans le tubage. Un mélange de fluides à haute pression (principalement de l'eau et du sable, avec des additifs chimiques) est pompé dans le puits, fracturant la roche environnante. Le sable (proppant) maintient ces fractures ouvertes, ce qui permet au pétrole ou au gaz piégé de s'écouler dans le puits et de remonter à la surface.

Tableau : Les 7 étapes de la procédure de forage

| Étape | Action primaire | Objectif principal |

|---|---|---|

| 1. Préparation du site | Arpentage, défrichement et nivellement. | Créer un emplacement sûr, stable et respectueux de l'environnement pour la plate-forme. |

| 2. Composants de l'appareil de forage | Transport et assemblage du derrick, du treuil, du système rotatif et du BOP. | Construire les machines complexes nécessaires au forage et au contrôle du puits. |

| 3. Techniques de forage | Sélection de la trajectoire du puits (verticale, directionnelle, horizontale). | Choisir le chemin le plus efficace pour atteindre la cible souterraine. |

| 4. Forage rotatif | Rotation du trépan et circulation de la boue de forage pour faire avancer le puits de forage. | Casser physiquement la roche et atteindre la profondeur cible tout en maintenant le contrôle du puits. |

| 5. Gestion des fluides | Circulation, nettoyage et contrôle des propriétés des boues de forage. | Assurer la stabilité du puits, enlever les déblais et contrôler les pressions souterraines. |

| 6. Opérations offshore | Adaptation du processus de forage à un environnement marin à l'aide de plates-formes et de colonnes montantes marines. | Surmonter les défis uniques du forage en eaux profondes. |

| 7. Fracturation hydraulique | Pompage d'un fluide à haute pression pour fracturer la roche une fois le forage terminé. | Stimuler le réservoir pour améliorer le flux d'hydrocarbures dans les roches compactes. |

Conclusion

Le passage d'une ressource potentielle à un puits de production est une merveille de l'ingénierie moderne, qui repose sur ces sept étapes critiques. De l'étape initiale préparation du site à la dernière, optionnelle processus de fracturation hydrauliqueChaque phase est conçue pour maximiser l'efficacité, garantir la sécurité et protéger l'environnement. Pour les professionnels du secteur énergétique américain comme pour les observateurs curieux, la compréhension de cette procédure démystifie la manière dont le pétrole et le gaz qui alimentent notre vie sont ramenés à la surface de manière responsable. Ame Drill Des progrès constants en matière de techniques de forage et l'optimisation des performances de forage veiller à ce que ce processus devienne de plus en plus sûr et efficace.