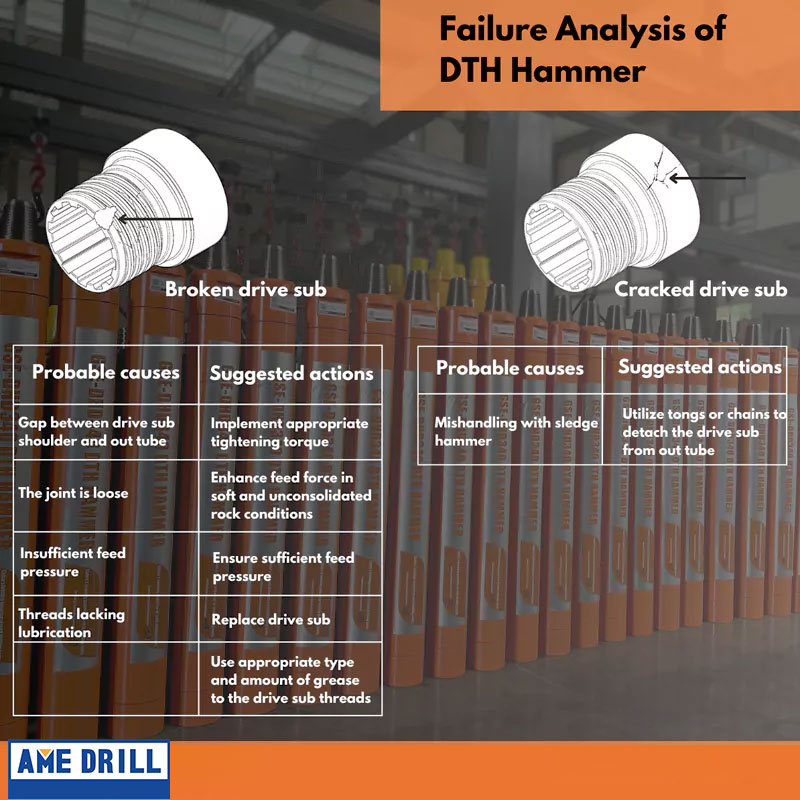

How to Solve Common DTH Hammer Failure?

Learn how to solve common DTH hammer issues, including broken or cracked drive subs, pistons, and out tubes, with proper maintenance, lubrication, and handling techniques.

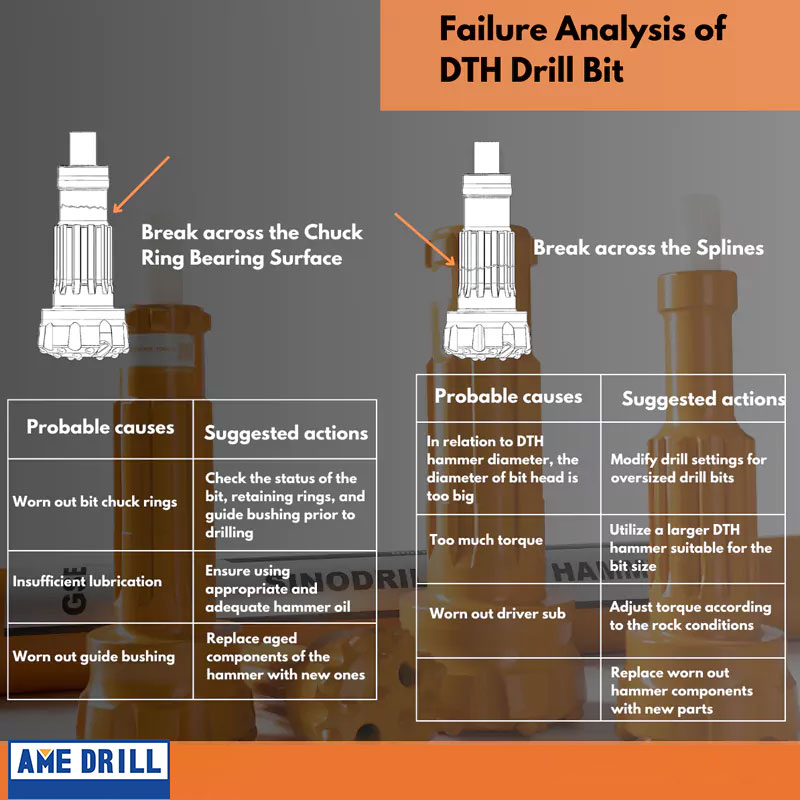

6 Ways to Solve DTH Drill Bits Failure

Discover 6 ways to fix DTH drill bit failures like spline breaks and piston damage with tips on lubrication, part replacement, and drilling parameter adjustments.

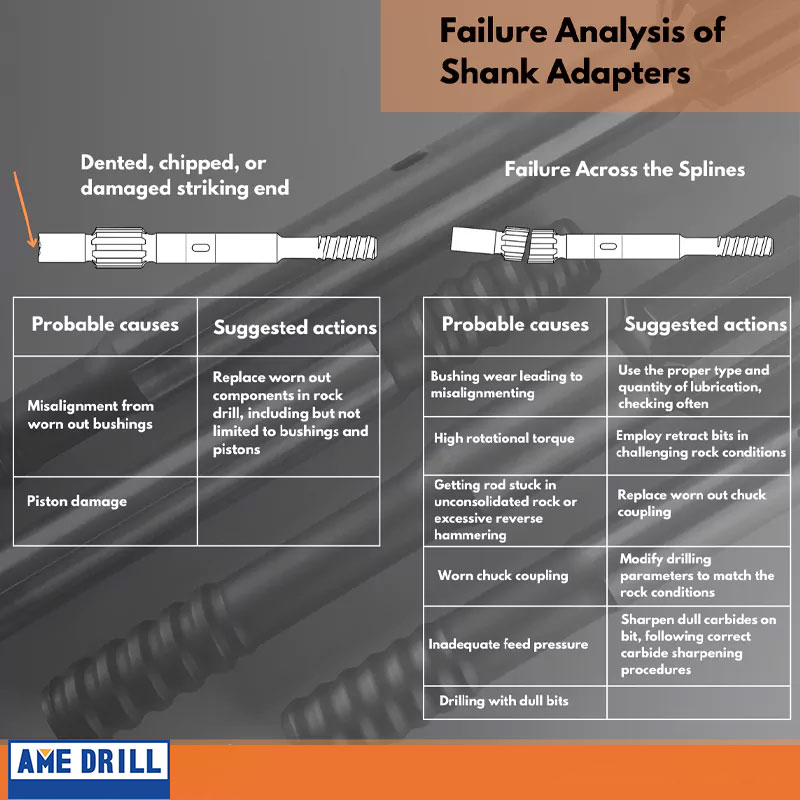

8 Ways to Solve Shank Adapter Failure

Learn 8 common causes of shank adapter failure in top hammer drilling and how to fix them to improve tool life and drilling efficiency.

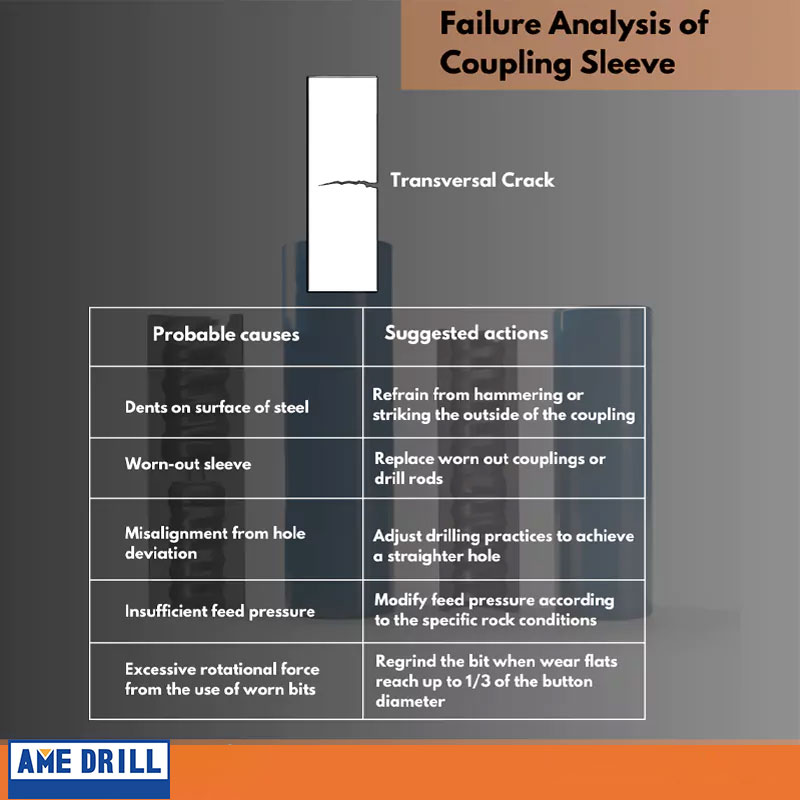

Failure Analysis Guide of Coupling Sleeves

Discover key tips to prevent shank adapter damage in hydraulic rock drills by addressing common wear issues and improving maintenance practices.

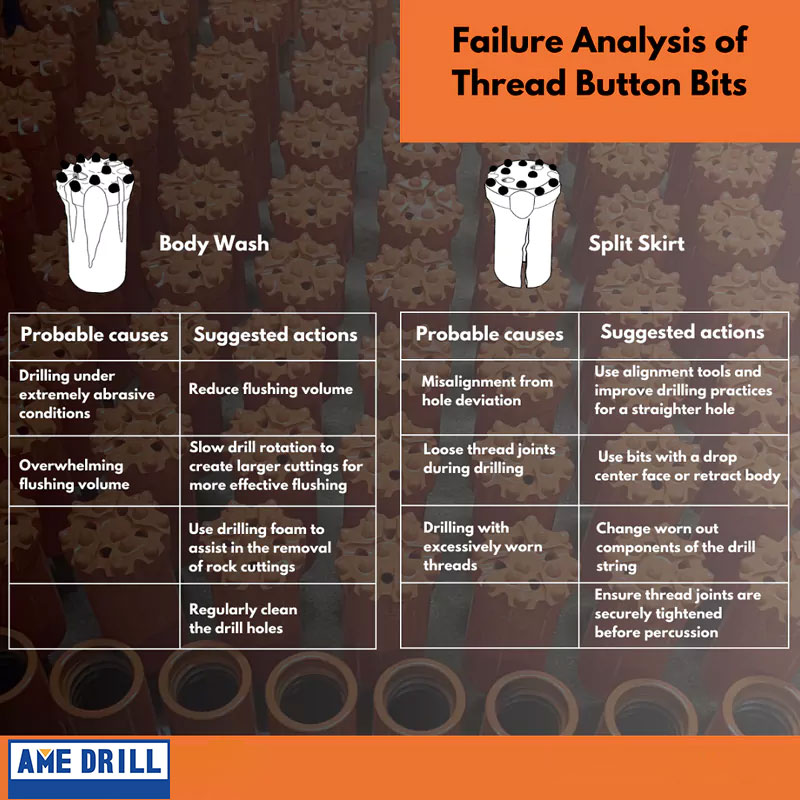

Everything about the Failure Analysis of Thread Button Bits

Explore common failures of thread button bits—like carbide pop-out and steel cracks—and learn how to prevent them with proper drilling practices and maintenance.

What’s the Friction Welding Process for DTH Drill Pipes?

Friction welding creates strong DTH drill rod joints using heat from friction and pressure, offering high strength, efficiency, and eco-friendliness for drilling use.

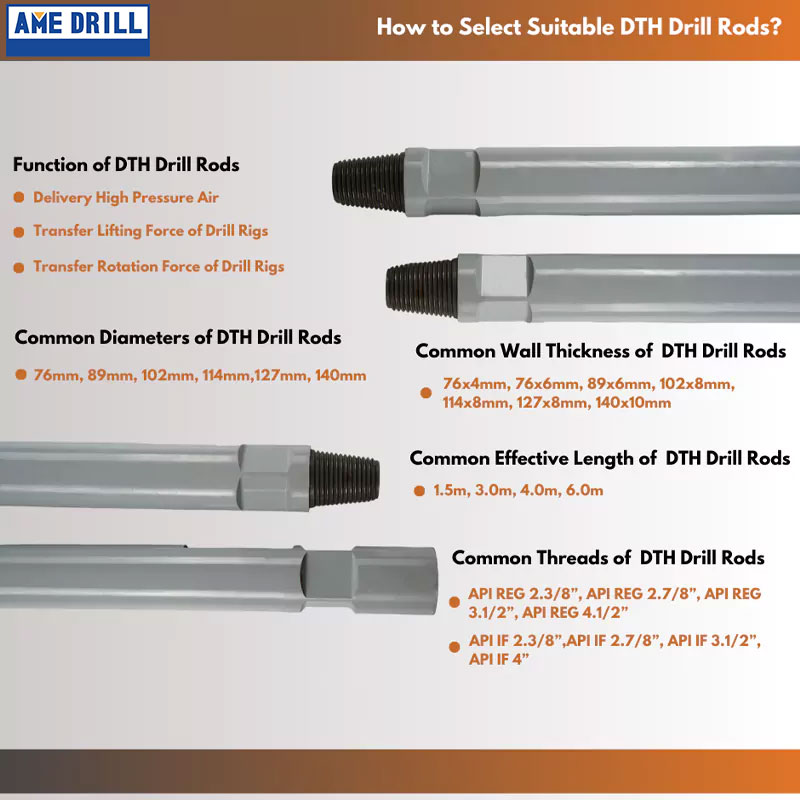

How to Select Suitable DTH Drill Pipes/Rods?

Learn how to choose the right DTH drill rods by considering diameter, length, thread type, and project needs to boost drilling efficiency and reduce costs.

What’s the History of the Anchor Drill Rigs?

Anchor drill rigs evolved from manual tools in the 1950s to advanced, automated systems with high torque and multifunctional features for modern tunneling and mining.

What’s the History of the Anchoring Technology?

Anchoring technology advanced from simple rock bolts to modern systems with higher load capacity, enhancing safety and efficiency in mining and geotechnical engineering.

What Everyone Ought to Know About the History of DTH Hammers?

Explore the evolution of DTH hammers from their invention in 1932 to modern advancements, including valveless designs and high-pressure capabilities, enhancing drilling efficiency.