The best DTH drilling bits are manufactured to match the shank and diameter of the Martillos DTH. The bodies of quality bits are precision machined from the alloy steel, heat treated to a specified hardness, providing surface compression for fatigue resistance, and then fitted with precision carbide buttons.

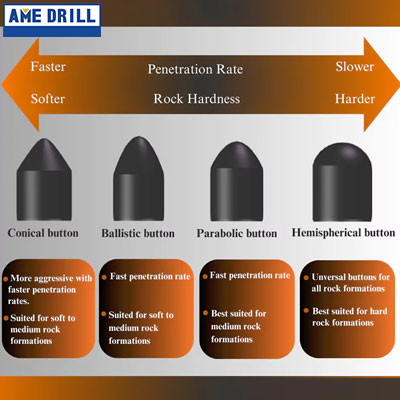

A variety of bit designs and configurations are available for all rock types, focusing on rock psi hardness and application conditions. The bit life and the rate of penetration are the most important criteria in selecting the right bit for a particular application.

The convex-faced, ballistic-button designs are preferable for the fastest cutting removal. This bit design cuts clean with minimal re-crushing, making it ideal for the soft to medium, non-abrasive formations.

In a hard and abrasive formations, flat-front designs offer the best bit life, especially those that feature strong gauge rows with large spherical buttons that are easy to regrind and maintain. An alternative in these conditions is a concave design with spherical buttons. The concave bit faces work well in the medium to hard, fractured formations. In this type of application, a concave bit minimizes hole deviation.