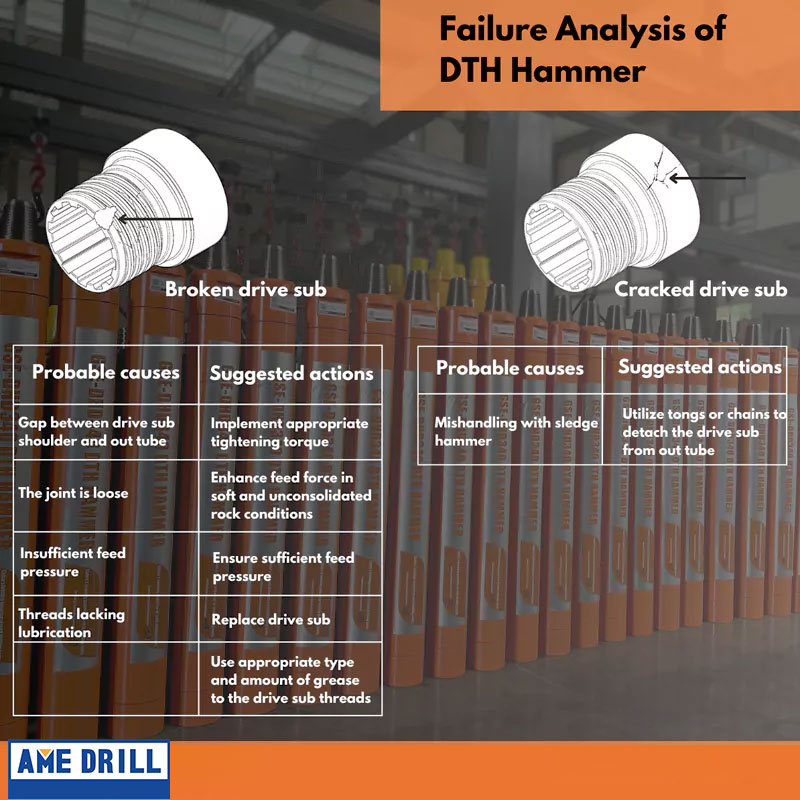

¿Cómo solucionar los fallos habituales de los martillos de fondo?

Learn how to solve common DTH hammer issues, including broken or cracked drive subs, pistons, and out tubes, with proper maintenance, lubrication, and handling techniques.

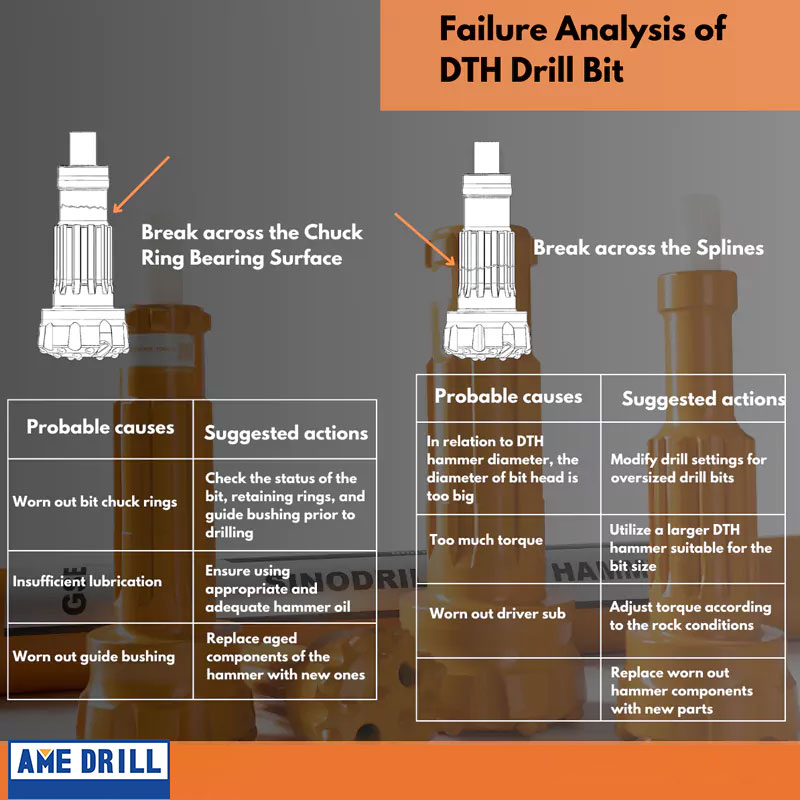

6 formas de solucionar los fallos de las brocas DTH

Discover 6 ways to fix DTH drill bit failures like spline breaks and piston damage with tips on lubrication, part replacement, and drilling parameter adjustments.

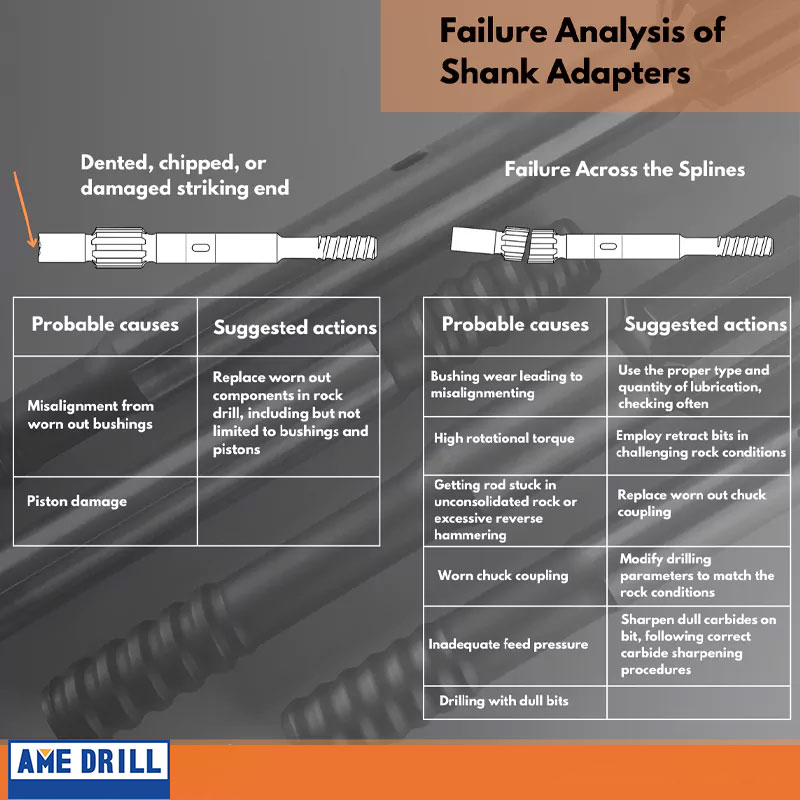

8 formas de solucionar los fallos de los adaptadores de vástago

Conozca 8 causas comunes de fallo del adaptador del vástago en el taladrado con martillo en cabeza y cómo solucionarlas para mejorar la vida útil de la herramienta y la eficacia del taladrado.

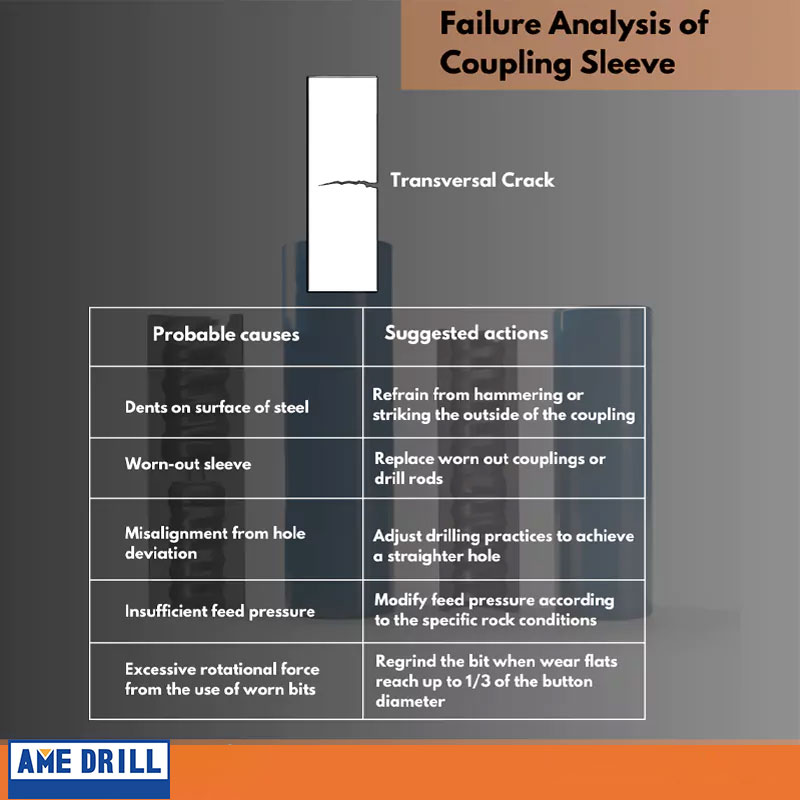

Guía de análisis de fallos de los manguitos de acoplamiento

Descubra consejos clave para evitar daños en el adaptador del vástago de las perforadoras hidráulicas para roca abordando problemas comunes de desgaste y mejorando las prácticas de mantenimiento.

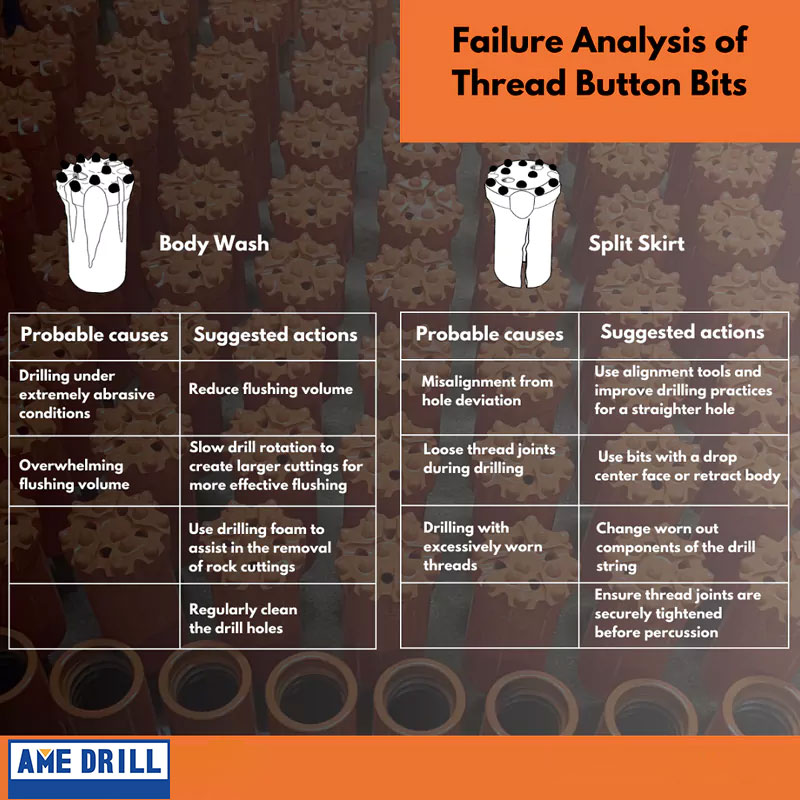

Todo sobre el análisis de fallos de las brocas de botones de rosca

Explore los fallos más comunes de las brocas de botón roscado -como el desprendimiento del carburo y las grietas en el acero- y aprenda a prevenirlos con unas prácticas de taladrado y un mantenimiento adecuados.

¿Qué es el proceso de soldadura por fricción para tubos de perforación DTH?

Friction welding creates strong DTH drill rod joints using heat from friction and pressure, offering high strength, efficiency, and eco-friendliness for drilling use.

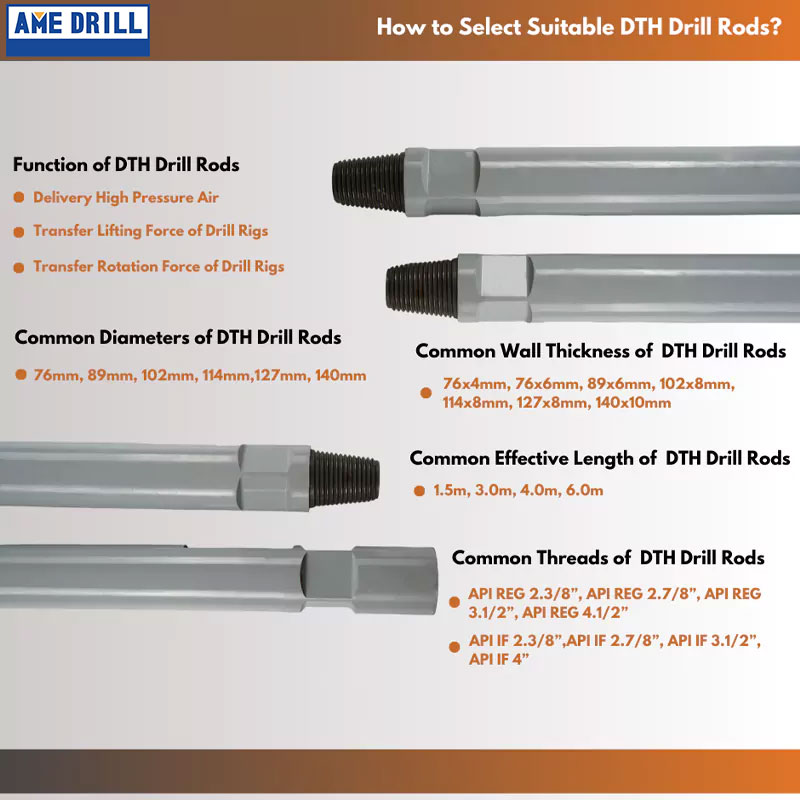

¿Cómo seleccionar los tubos/varillas de perforación DTH adecuados?

Learn how to choose the right DTH drill rods by considering diameter, length, thread type, and project needs to boost drilling efficiency and reduce costs.

¿Cuál es la historia de los equipos de perforación con anclaje?

Anchor drill rigs evolved from manual tools in the 1950s to advanced, automated systems with high torque and multifunctional features for modern tunneling and mining.

¿Cuál es la historia de la tecnología de anclaje?

Anchoring technology advanced from simple rock bolts to modern systems with higher load capacity, enhancing safety and efficiency in mining and geotechnical engineering.

¿Qué debe saber todo el mundo sobre la historia de los martillos en fondo?

Explore the evolution of DTH hammers from their invention in 1932 to modern advancements, including valveless designs and high-pressure capabilities, enhancing drilling efficiency.